SOI/TD 2005-2 PR

25/26

599 36 83-66

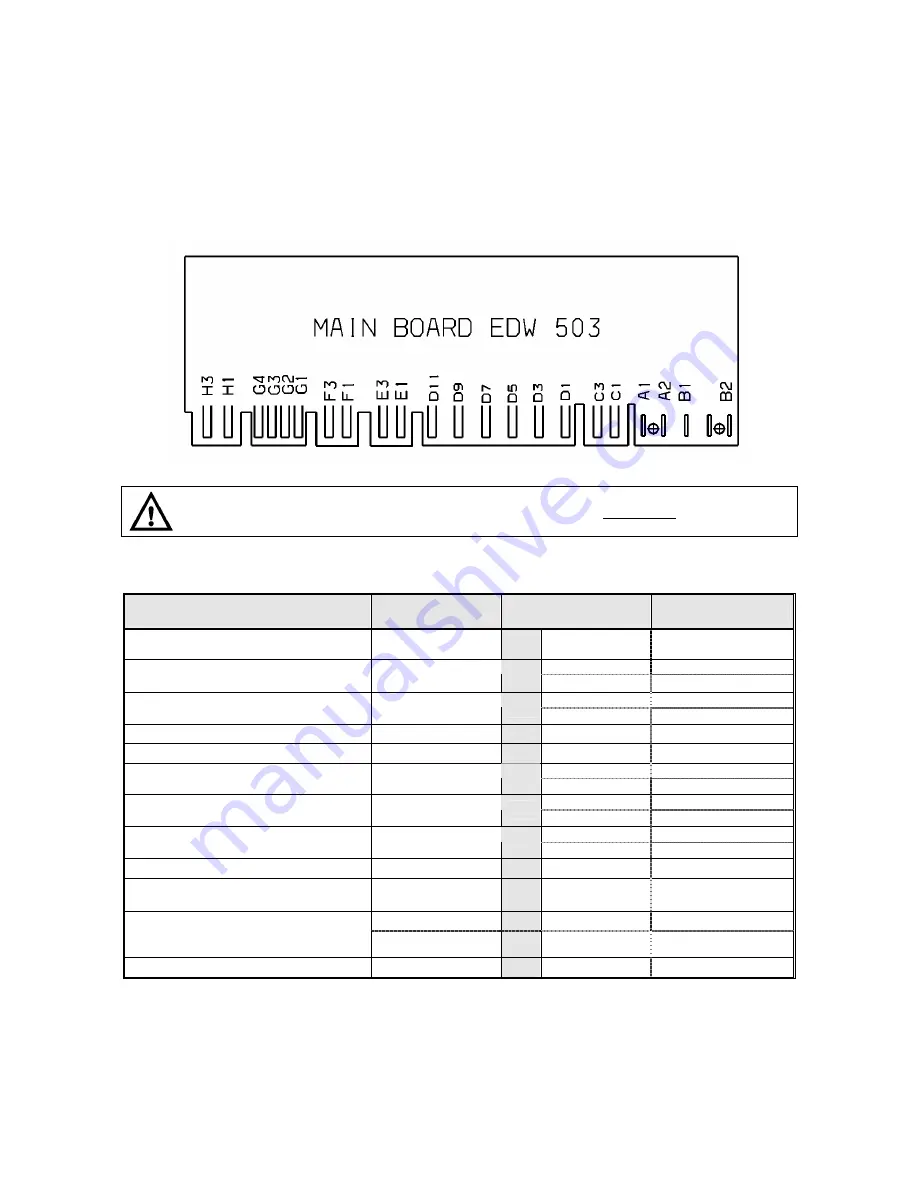

14 CHECKING THE EFFICIENCY OF THE COMPONENTS

In order to facilitate the control procedure for the components to be tested, a TEST PROCEDURE has been

created which indicates the point to which the probes of the tester should be applied and the correct

theoretical value for each component tested.

Remove the door and detach all the connectors from the main board.

Connect the probes of the tester to the appropriate points on the connector. Compare the ohmic reading

with the theoretical value

.

Care should be taken relative to the position of connector "

B1

" - "

B2

": if this connector is

replaced in the incorrect position (back-to-front), the appliance will not function since the power

supply will be disconnected.

14.1 Measurement points on the board wiring connectors

LIST OF COMPONENTS

PROBE

CONTACTS

CORRECT VALUES

NOTES

(RR) - HEATING ELEMENT

+

(TS) - SAFETY THERMOSTAT

A1 D5

25

Ω

±

8%

connected in series

(2100W)

INFINITE

on "EMPTY” (1-2)

(PR) - LEVEL PRESSURE SWITCH

D5 instead of A1

A2

0

Ω

on "FULL" (1-3)

INFINITE

on "EMPTY (1-2)

(PA) - ANTI-FLOODING PRESSURE

SWITCH

D1 B2

0

Ω

on "FULL" (1-3)

(IP) - DOOR MICROSWITCH

C1 C3

0

Ω

Door closed

(DD/DB) - INTEGRATED DISPENSER

E1 E3

1.500

Ω

± 8%

OK

INFINITE

with Rinse-aid

(SB) - RINSE-AID SENSOR

G3 G4

0

Ω

without Rinse-aid

INFINITE

with salt

(SS) - SALT SENSOR

G1 G2

0

Ω

without salt

4850

Ω

± 5%

(at

25ºC)

(ST) - TEMPERATURE SENSOR

H1 H3

1205

Ω

± 5%

(at

60ºC)

(ER) - REGENERATION SOLENOID

C1 D9

6 K

Ω

± 8%

OK

(EC) - FILL SOLENOID

+

(AA) - ANTI-FLOODING DEVICE

D7

C1 instead of D11

3.800

Ω

± 8%

connected in series

D3 D11

50

Ω

± 8%

start-up winding

(PL) - WASH MOTOR

To the 2 motor wires

(bl) / (ro)

180

Ω

± 8%

auxiliary winding

(PS) - DRAIN MOTOR

D1 C1

180

Ω

± 8%

OK