44

GB

5938 033 01

cool -

Oven cooling on.

ECLO -

Clock error appears if the time has never been adjusted.

To eliminate the error set the time.

End

- End of a cycle or function.

FILL -

Boiler filling. (Ensure water supply tap/cock are open).

LOAd

- Place the food in the oven.

oPEn -

Boiler discharge valve opening.

PrEH

- (TIME

TM / PRB

DISPLAY)Boiler preheating.

PrEH

-(COMPARTMENT TEMP. DISPLAY

TS

) Automatic

compartment preheating.

Soap

- Detergent. Spray a suitable product on the surfaces to be

cleaned as indicated in point 4) of the semiautomatic chamber

cleaning cycle (see par. 7. CARE AND MAINTENANCE).

Strt -

Press the START button to start the program.

Stby

- CLEANING SYSTEM cleaning standby time.

ERROR codes

Codes indicating the need to call technical service

EH2O -

Water supply pressure too low for CLEANING SYSTEM

(pressure requirements from 1.5 to 2.5 bar).

EFUN -

Fan automatic reset thermal switch device. UP appears

on the small DISPLAY with reference to the single fan (6-10

GN) or upper fan (20 GN) of the chamber and DO in reference

to the lower fan (only 20 GN).

E—-

- Non-compliance with a parameter requirement (number

of parameter appears in place of dashes “—”).

EPt1 -

Chamber sensor interrupted or short-circuited.

EPt2 -

Boiler sensor interrupted or short-circuited.

EPt3 -

Probe sensor interrupted or short-circuited.

EPt4 -

Bypass sensor interrupted or short-circuited.

EPt8 -

Electronic controller temperature sensor damaged.

ESCH -

Malfunction of commands control circuit cooling devices.

Etub -

Boiler overtemperature (125°C) warning.

Etuc -

Chamber overtemperature (320°C) warning.

EFLP -

Fault in chamber steam discharge motor-operated valve.

ETC -

Tripping of chamber temperature limiter.

ETB -

Tripping of boiler temperature limiter.

IMPORTANT!

If an error code is displayed during a cooking cycle, the oven

emits a continuous audible warning signal and the cooking

cycle is interrupted.

In this case the oven can be used only in cooking modes that

do not involve the conditions that generated the error.

Notify your Technical Service Centre of the alarm code

displayed.

6. SWITCHING OFF IN THE EVENT OF A FAULT

If the appliance malfunctions, switch off as follows:

• Switch off the automatic circuit breaker upline from the appliance

and turn off the water cocks .

• Contact a service centre with personnel trained and authorised

by the manufacturer.

7. CARE AND MAINTENANCE

• At the end of each day clean the oven interior with an oven

cleaner, following the product supplier's directions.

• Do not wash the appliance with water jets.

• Do not clean steel surfaces with products containing chlorine

(bleach, hydrochloric acid etc.) even diluted.

• Do not use corrosive substances (e.g. muriatic acid) to clean the

floor under the appliance.

A

and

C

(

B

, if fitted) LEVEL the appliance has an automatic

compartment cleaning programme called CLEANING SYSTEM;

for its use see par. 1.4.3 USING PRESTORED PROGRAMMES

for LEVEL

A,

whereas for LEVEL

C

(

B

, if fitted)

see below.

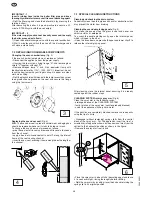

The CLEANING SYSTEM program uses detergent and rinse aid.

Therefore, fill the DETERGENT container - max. 5 litres (on the

RIGHT with RED cap) and the RINSE AID container - max. 1,2

litres (on the LEFT with BLUE cap) located under the control

panel:

RINSE AID_________________ __________DETERGENT

max. 1,2 litres

max. 5 litres

For models 20GN1/1-2/1 connect the tubes (supplied) on the left

side of the oven (RH connection RED symbol for DETERGENT;

LH connection BLUE symbol for RINSE AID) and insert the other

ends in their respective containers (not supplied) fi lled with

DETERGENT and RINSE AID.

To ensure best cleaning results, as well as to protect the oven

with the integrated CLEANING SYSTEM, the following detergents

must be used:

ELECTROLUX "ExtraStrong Clean for Oven" - Detergent

(Code 0S1192)

ELECTROLUX "ExtraStrong Rinse for Oven" - Rinse Aid

(Code 0S1193)

Do not use detergent or rinse aid powder dissolved in water or

in gel form and containing chlorine.

ATTENTION:

The warranty does not cover damage caused by the use of deterg

ents and rinse aids not complying with the above characteristics.

- Detergent and rinse aid containers, independent of the oven,

must not be placed higher than the appliance support surface (for

model 6 GN they must be placed lower than the oven support top).

The oven features a UTILITY to perform a automatic or

semiautomatic oven chamber cleaning cycle. Proceed as follows.

In the level

A

oven, carry out the AUTOMATIC cleaning cycle by

following the instructions in par. 4.4.6 CLEANING SYSTEM.

----------

AUTOMATIC (

C

) (

B

, if fitted)

---------

and SEMIAUTOMATIC (

A-B-C

) cycle

1) - Remove any large food remnants using a water jet.

Do not use the spray shower or water jets to quickly cool the

compartment and the inside glass of the oven door.

2) - Set the following UTILITY as described in heading 4.3.9

UTILITIES: