22

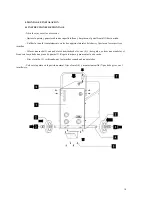

4.2 CONNECTION TO THE MAIN SUPPLY

This unit must be connected to a single phase 230V or 400V - 50 Hz/60 Hz + ground. . The selection of the

mains voltage should be done by putting the security disk of the voltage selector switch as refered in the machine's

frontal panel.

Main supply must be protected by fuses or circuit-breaker according to the value I1eff written on the

specifications of the power source.

It is strongly suggested to use a differential protection for the operator’s safety.

4.3 CONNECTION TO EARTH

For the operator's protection, the power source must be correctly grounded (according to the International

Protections Norms).

It is absolutely necessary to set a good earth connection with the green/yellow wire of the power cable. This

will avoid discharges caused by accidental contacts with grounded pieces. If no earth connection has been set, a high

risk of electric shock through the chassis of the unit remains possible.

5. WELDING

Connect the power source to the main supply and the ground.

Connect the ground cable and the electrode holder to the appropriate power connections.

Start up the power source with the switch ON/OFF, selecting the appropriated input voltage according to

mains.

The red indicator illuminates and indicates that the machine is under voltage.

Adjust welding current with potentiometer.

Place the electrode on the piece you have to weld in order to strike the arc.

6. MAINTENANCE

The arc welding equipment should be routinely maintained according to the manufacturers’ recommendations.

All access and service doors and covers should be closed and properly fastened when the arc welding equipment is

in operation. The arc welding equipment should not be modified in any way, except for those changes and

adjustments covered in the manufacturer’s instructions. In particular, the spark gaps of arc striking and stabilising

devices should be adjusted and maintained according to the manufacturer’s recommendations.

Before carrying out any internal checking or repair work, check that the power source has been disconnected

from the electrical installation by locking and guard devices. Ensure and avoid accidental connection of the plug to a

socket. Voltages are high and dangerous inside the machine.

In spite of their robustness, ours power sources require some regular maintenance. Each 6 months (more often

in dusty surroundings):

- The machine must be blown through with dry, oil free compressed air.

- Check for continuity all electrical connections.

- Check the connection of cables and flat top.

Check the good state, insulation and connection of all the equipment and electrical accessories: plugs and

flexible supply cables, conduits, connectors, extension cables, sockets on the power source, ground clamp and

electrode holder. These connections and mobile accessories are marked according to standards, if consistent with the

safety rules. They can either be controlled by you or by accredited firms.

-Repair or replace all defective accessories

-Check periodically that the electrical connections are tightened and do not heat.

Maintenance works of electrical equipment must be entrusted by qualified people (Section VI, Art. 46).

For 230V mains supply

For 400V mains supply

Positioning of security disk