9 MAINTENANCE

Carefully read the "Safety" section of this manual before

carrying out any maintenance operations.

Planned maintenance

Operations

yli

a

D

yl

k

e

e

W

yl

ht

n

o

M

g

ni

n

ni

g

e

B

n

o

s

a

e

s

f

o

n

o

s

a

e

s f

o

d

n

E

Check the temperature

of the leaving fluid

Check the pressure drops

in the heat exchanger

Check for electric absorption

Check suction pressure

and temperature

Check delivery pressure

and temperature

Check that the fins of the

external coil are clean (if any)

Check the operation of the

oil heaters (if any)

Check the remote control

switches

Check the operation of the

LP pressure switch

Check the operation of the

HP pressure switch

Check the insulation of the

heat exchanger

Check that terminals are

tightened

Check that the terminals'

screws are tightened

Clean the exterior of the

unit with water and soap

Check the density of the

antifreeze (if any)

Do not discharge the refrigerant into the atmo-

sphere while the refrigeration circuits are

being drained. Use appropriate recovery equip-

ment. When the recovered refrigerant cannot

be re-used, return it to the manufacturer.

Do not throw away the waste oil of the

compressor, because it contains refrigerant in

solution. The waste oil must be returned to the

manufacturer.

Unless otherwise specified, the operations described below

may be carried out only by a trained maintenance operator.

9.1 General requirement

The units have been designed for continuous operation,

providing that they are subjected to regular maintenance,

within the limits specified in this manual. Each unit must be

serviced according to the programme by the User/ Customer,

and must be inspected at regular intervals by the personnel

of one of the authorised Service Centers.

It is the responsibility of the User to meet these maintenance

requirements and/or to enter into an agreement with one of

the Authorised Service Centers, so as to properly safeguard

the operation of the appliance.

The provisions of this section apply only to standard units;

according to the order requirements, other documentation

may be added, concerning any modifications or supplemen-

tary accessories.

Maintenance inspections must be carried out according to

the program below, by a qualified person. As a general rule,

units cannot be repaired directly by the user, who shall not try

to service or repair any failures or anomalies identified during

daily inspections. If you are in doubt, please contact the

authorised Service Centre.

9.2 Planned maintenance

Maintenance

English

During the warranty period, in case of damage or failures

caused by improper maintenance the manufacturer will not

refund the costs incurred to repair the appliance to its original

state.

Summary of Contents for MQH 10T

Page 1: ...Zertifizierungsstelle Organismo Notificado No 0035 Библиотека СОК ...

Page 2: ...I X English ...

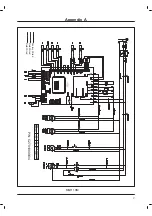

Page 42: ...VII Appendix A MQH 10T 12 14 16 18 C27019300 04 Factory Wired Field Wired Field Wired ...

Page 44: ...IX Appendix B Exploded View MQH 06 08M 08T ...

Page 45: ...X Appendix B MQH 10M 10T 12 14 16 18 ...

Page 46: ......

Page 47: ...Electra Air Conditioning shenzhen Co Ltd 2 Wuhe Avenue S Bantian Buji shenzhen China ...