13

8. If an audible indication is not required, switch the

MODE

control back to DEPth.

CAUTION – Whenever possible, use the audible indication until you are

absolutely certain of the layout of the reinforcing bars. Having the audible

indication sounding does NOT significantly decrease operating hours.

4.3 Irregular bars

The

CM52 CoverMaster

is factory-calibrated for round ribbed high-tensile bars, and

correctly indicates the minimum depth of cover from the surface to the closest peaks of

the ribs. The depth of cover over smooth round bars will thus be slightly underestimated,

though this is rarely of practical importance (if it is, see section 6 on RECALIBRATION).

For some structures, an acceptable alternative to a single large reinforcing bar is a bundle

of smaller bars with the same total cross-sectional area – typically two, three or four bars.

The most common arrangement is two lapped bars – see section 5.7 for further details.

As a general rule, select the diameter of one bar, then move the

DIAM

control one click

clockwise for each extra bar in the bundle.

Square-section bars are occasionally found in older structures. For these bars, turn the

DIAM

control to the setting nearest to 1.1 times the width of a side. Sometimes a square

bar may be twisted so that its orientation varies continuously from flat to edge-on. Where

the bar is edge-on to the surface of the concrete, the minimum depth of cover will be

underestimated by 25% of the effective diameter which was set using the

DIAM

control.

Where the bar is lying flat beneath the surface of the concrete, the minimum depth of

cover will be overestimated by 11% of the effective diameter. As a general rule for twisted

square bars, set the

DIAM

control to the width of a side, or one larger. Then the cover

can generally be estimated within (–25, +11)% of the effective diameter chosen.

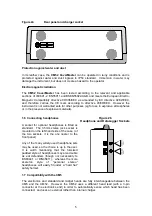

4.4 Shallow depths

If the indicated cover depth is less than about 27mm, the instrument warns you by

deliberately changing the display to ‘000

m

’ rather than lose accuracy. In such cases, you

may turn the search head over and use the white face. This adds exactly 30mm to the

depth below the search coils and restores full accuracy.

When using the white face, always remember to

subtract 30mm from the indicated

reading

. Do not use the white face unless it is necessary. If the cover is only just under

27mm, it will be more accurate to put a spacer of only 10mm between the concrete and

the black face of the head – see section 5.5 later.

Section 5.4 gives further information on resolving multiple shallow bars.

But for shallow cover, and especially if the bars are closely-spaced,

use the Midget Head

in preference to the white face of the standard head, as described later in section 5.12.

This completes the instructions for inexperienced users and normal situations. Sections 5

and 6 deal with advanced techniques for using the CM52 CoverMaster in more difficult or

specialised situations.