DK50

SM-DK50-EN-1-08-2014-MD

08/2014

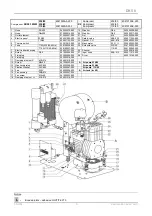

6. SWITCHING THE COMPRESSOR ON

(Fig.5)

Switch on the compressor at the pressure switch (2) by turning the knob (3)

to position “I.”, The compressor sends pressurized air to the air tank. As

the compressed air is used, the pressure in the air nozzle drops to a preset

level, the compressor switches on and the air nozzle files with compressed

air. After reaching the cutoff pressure the compressor turns off

automatically and the cycle is repeated. Check the value of switching-on

and switching-off pressure on pressure gauge. The values may be within a

tolerance of

10%. Air pressure in air chamber must not exceed maximal

permitted operation pressure.

Never tamper with the pressure switch (2). Adjustments are not allowed. The pressure

switch (2) has been set by the manufacturer and further setting of switching on and off

pressure may be carried out only by a qualified expert trained by the manufacturer.

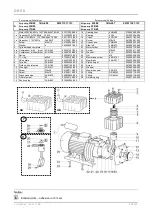

MAINTENANCE

7. MAINTENANCE SCHEDULE

Notice!

The operating entity is obliged to ensure that all tests of the equipment are carried out repeatedly at

least once within every 24 months (EN 62353) or in intervals as specified by the applicable national

legal regulations. A report must be prepared on the results of the tests (e.g.: according to EN 62353,

Annex G), including the measurement methods used.

Time interval

Maintenance that must be performed

Chapter Performed

by

1 x day

Release condensate

- At high air humidity

- Compressor without air drier

Compressors with air drier

Compressors with condensation unit :

- from filter

- from pressure vessel

8.1

operating staff

1 x week

1 x year

Check safety valve

8.2

qualified

technician

Replacement of filter element in filter and

micro-filter

8.4

8.5

operating staff

Replacement of filter in condensation unit

8.6

qualified

technician

Check tightness of joints

Overall examination of device

Service

documentation

qualified

technician

1 x 2 years

Perform “Repeated Test” according

to EN 62353

7

qualified

technician

1 x 4 years or after 8000 hours

Replacement of input filter

8.3

qualified

technician

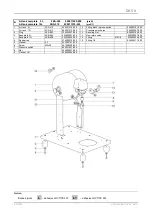

8. MAINTENANCE

Repair work beyond normal maintenance can be performed only by qualified personnel or

the manufacturer’s representative.

Use only spareparts and accessories approved by the manufacturer.

Prior to any maintenance or repair work, switch off the compressor and disconnect it from

the mains (pull out the mains plug).

TO ENSURE THAT THE COMPRESSOR WORKS CORRECTLY, PERFORM THE FOLLOWING

MAINTENANCE TASKS AT REGULAR INTERVALS (CHAPTER 7).:

Fig.5

3

5

2

1

4