EFA breastbone cutter Z 10 D

Translation of the operating instructions

EN

V 05.2021

14 of 21

2

3

4

1

5

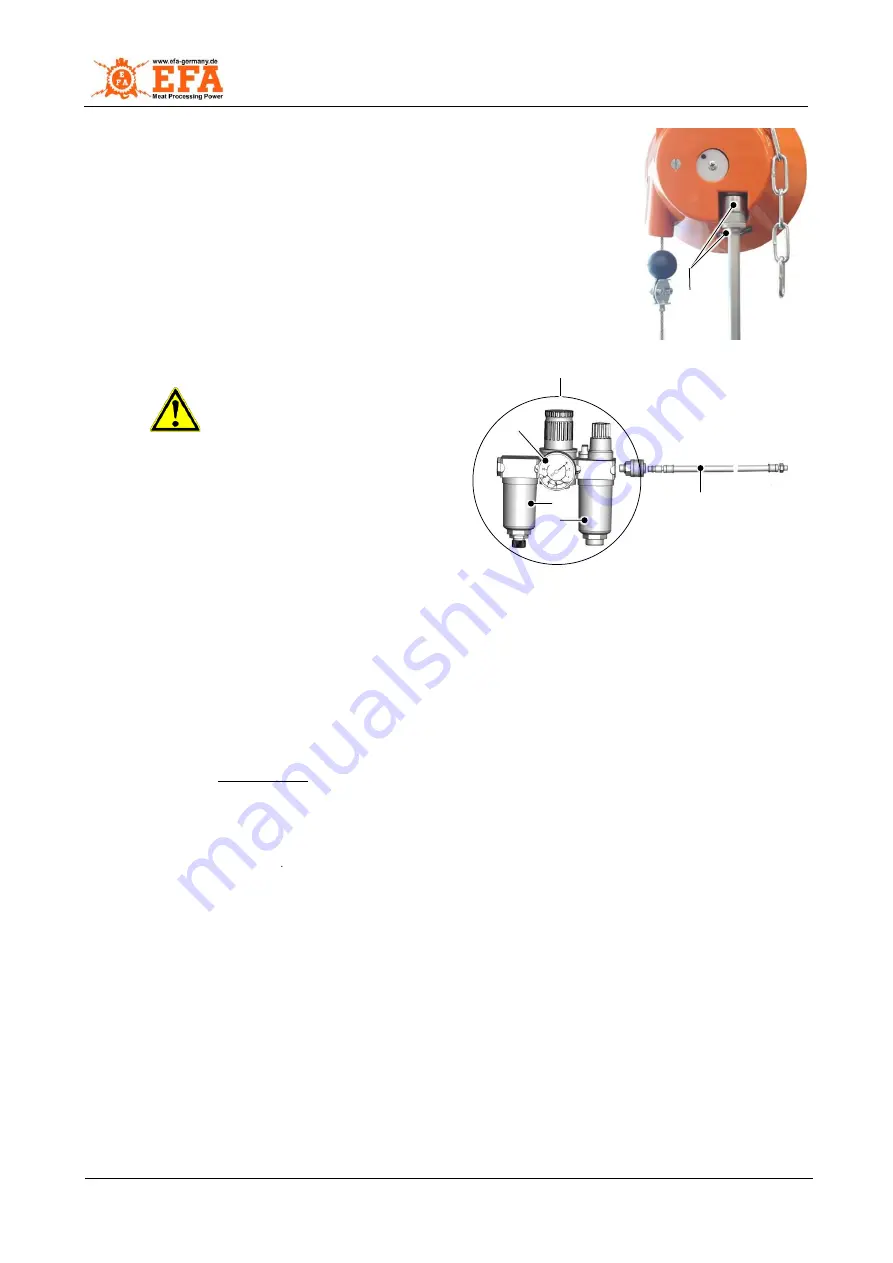

Fig. 5.4

– Oil mist lubricator

6

3

Adjustment of the spring balancer

The fine-tuning of the spring balancer is carried out via the plus/minus

(+/-) hexagon screw on its housing.

To do this, turn the screw with the socket wrench (3) in the direction of

minus (-) until the device is freely suspended and balanced (with the

tension spring) at the working height.

If it is not possible to pull out, the spring balancer is blocked and

readjustment is necessary.

Turn the screw with the socket wrench (3) in the direction of plus (+) until

pulling out is possible and start the fine adjustment again.

5.1.2

Oil mist lubricator

It must be connected via an oil mist lubricator of min.

R

3

/

8

".

The supply line for connecting the machine must have

at least

3

/

4

".

The air hose should be blown through before

connection.

Mount the oil mist lubricator (1) in the following sequence,

see Fig. 5.3

:

Water separator (2),

Set pressure gauge (3) to 6

– 8 bar,

Oil mist unit (4),

Air hose (5),

Connection of the breastbone cutter (6).

The oil mist lubricator must be set to 1 drop of oil per 5 cuts so that the lubrication of the pneumatic cylinder is

ensured.

Check the oil mist lubricator at regular intervals, however at least 1x per week, remove the condensation and

top up with EFA special oil.

Caution!

Tripping hazard!

We recommend that the lines are led

away upwards.

Lines that run along the floor can

be a tripping hazard for the

operator!

Fig. 5.3

– Setting of the

spring balancer