Page 11

OMNI by EconoHeat

Oil Flow Control Supply Pump has the ability to control lame even when various viscosities are

used- furnace or stove oil to 90 weight straight- lame remains stable

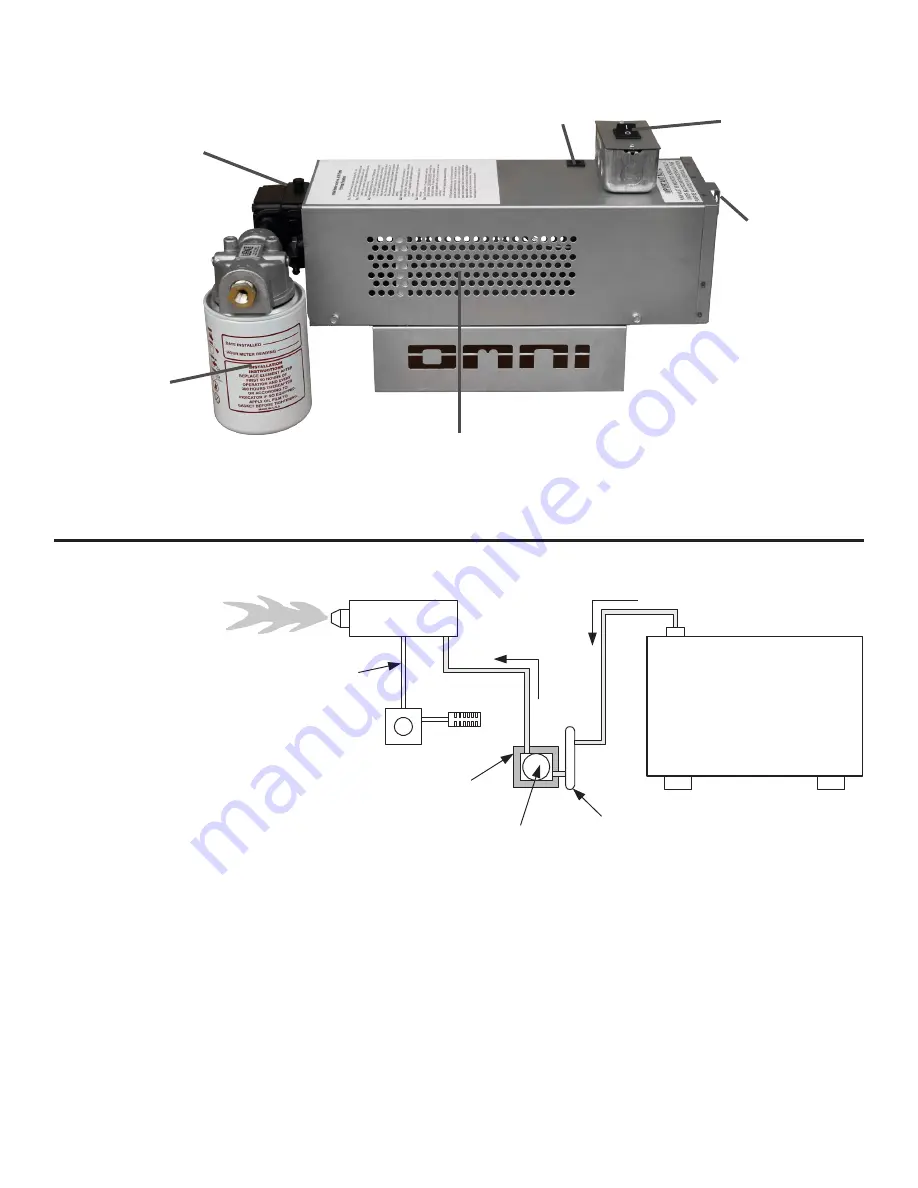

Figure 7 –

Oil Pump Assembly

Oil Shut-off Valve

(Eliminates start delays due

to possible drain back)

Spin-On Filter

Oil Primer Switch

(Solenoid valve, on/off)

Adjustable

Motor Speed

(Initial set up only; Once

set, no adjustment

needed thereafter)

Inline Breaker

Oil Burner Technology

OMNI’s patented burner technology improves the eficiency of the oil burn process by

continuous stabilization of the oil viscosity. Optimum atomization (spray) is accomplished

by precisely pre-heating the oil and air prior to introduction to the combustion chamber.

The waste oil enters into the Oil Pre-Heater Block (igure 4) and is pre-heated to operating

thermo setpoint, then compressed air from the air compressor (igure 3) is mixed with the oil

prior to spraying out the nozzle similar to fuel injection, by breaking up the oil droplets into a

iner mist or spray (atomization). Electrodes mounted just above the nozzle (igure 5) provides

continuous electrical arc across electrode to electrode igniting the ine oil mist as it sprays out

of the nozzle. Once ignited the lame is forced into a swirl caused by the burners blower and

specially designed lame cone (igure 5) providing a very eficient and thorough burn of the

waste oil.

DC Motor

Oil Tank

Filter

Flow Control

Oil Pump

Internal Pump Filter

Air Compressor

On Burner

Oil Preheater

Inside Burner

Air Line to Preheater

Mixes with Oil at Nozzle

Suction Line

Pressure Line

Atomization Through Low Pressure

Preheat & Air Induction At Nozzle

Air Filter