2.2

Maintenance

Eco Power Equipment Recommends all customers integrate a routine maintenance for all mobile power distribution

equipment. This equipment has been designed to provide mobile power distribution and as such we recommend our

customer implement a routine maintenance program:

1. Torque Check Procedure: All mobile power distribution should undergo regular torquing procedures before use.

This procedure should be developed based on the movement and usage of the equipment. With regular

checking and verification of critical connection points, here are some examples:

a. Hubbell Bus Tab Connection Points: 107-inch lb (9 ft-lb)

b. MCCB Tab to Breaker Bolts: 288 in-lbs (24 ft-lb)

c. MCCB and other items have torque ratings directly labelled on the device

2. Thermal Inspection: Abnormal heating associated with high resistance or excessive current flow is the main

cause of many problems in electrical systems. Infrared thermography allows us to see these invisible thermal

signatures of impending damage before the damage occurs. When current flows through an electric circuit, part

of the electrical energy is converted into heat energy. This is normal. But, if there is an abnormally high

resistance in the circuit or abnormally high current flow, abnormally high heat is generated which is wasteful,

potentially damaging and not normal.

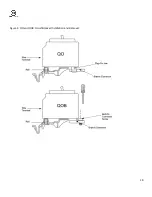

2.3 Setup Process

The setup and deployment process involved for the SBP-XFMR series power distribution panel involves locating the unit

on a level, suitable terrain, connecting earth ground, and connecting electrical distribution.

Before using the unit, be sure to read and understand all of the instructions. This equipment was designed for specific

applications; DO NOT modify or use this equipment for any application other than which it was designed for.

Equipment operated improperly or by untrained personnel can be dangerous.

Before using a unit visually inspect the unit for damage. A complete visual inspection of all power distribution

connections.

Equipment Spacing:

Eco Power Equipment recommends that SBP-XFMR type power transformers be mounted so that there is an air space of

no less than 305 mm (12”) between the enclosure and any adjacent wall unless otherwise marked. Furthermore, it is

recommended that a minimum air space of 610 mm (24”) be allowed above the transformer for adequate cooling. A

minimum working space of 762 mm (30”) is recommended for all removable access panels that provide access to

connections, and any renewable or adjustable parts / accessories. If the transformer must be located near a combustible

surface / wall, the minimum clearance established by the Local Electrical Code and Fire Marshal should be maintained.

11