13

Eclipse Packaged Gas BoostPak, V2, Installation Guide 630-2, 6/22/2010

Maintenance &

Troubleshooting

Monthly Checklist

• Inspect and tighten loose mechanical components

• Look for signs of damage and repair

• Test operation if the unit has not run and check for

excessive vibration

• Clean the booster motor housing

• Clean the heat exchanger, its motor, and cooling fan

(MH only)

• Wipe clean the control panel surfaces

Yearly Checklist

• Check inlet and outlet pressure switch settings

• Check and compare inlet and outlet pressures to the

initial commissioning record sheet

• Measure and compare the power supply and motor

current to the record sheet

• Perform operational test in the commissioning

section of this guide

Alarm Conditions

Certain conditions will cause the ALARM to come on. To

silence the alarm, press the ALARM SILENCE push

button.

• INLET LOW GAS MANUAL RESET PRESSURE

SWITCH opens due to low utility line pressure. The

LOW GAS light comes on and the booster motor will

stop running. When the pressure is restored, this

switch must be manually pushed to reset its contact.

• DISCHARGE GAS PRESSURE SWITCH fails to

make contact within 15 seconds. The LOW GAS

light comes on; the booster will not shut down.

• If the motor wiring or internal temperature switch

opens, then the motor will stop causing the

discharge gas pressure switch to open. Then the

ALARM and LOW GAS light come on.

• A booster motor overload condition will shut down

the booster and the MOTOR FAULT light and

ALARM will come on.

• A heat exchanger motor overload condition will shut

down the heat exchanger fan and the MOTOR

FAULT light and ALARM will come on (MH only).

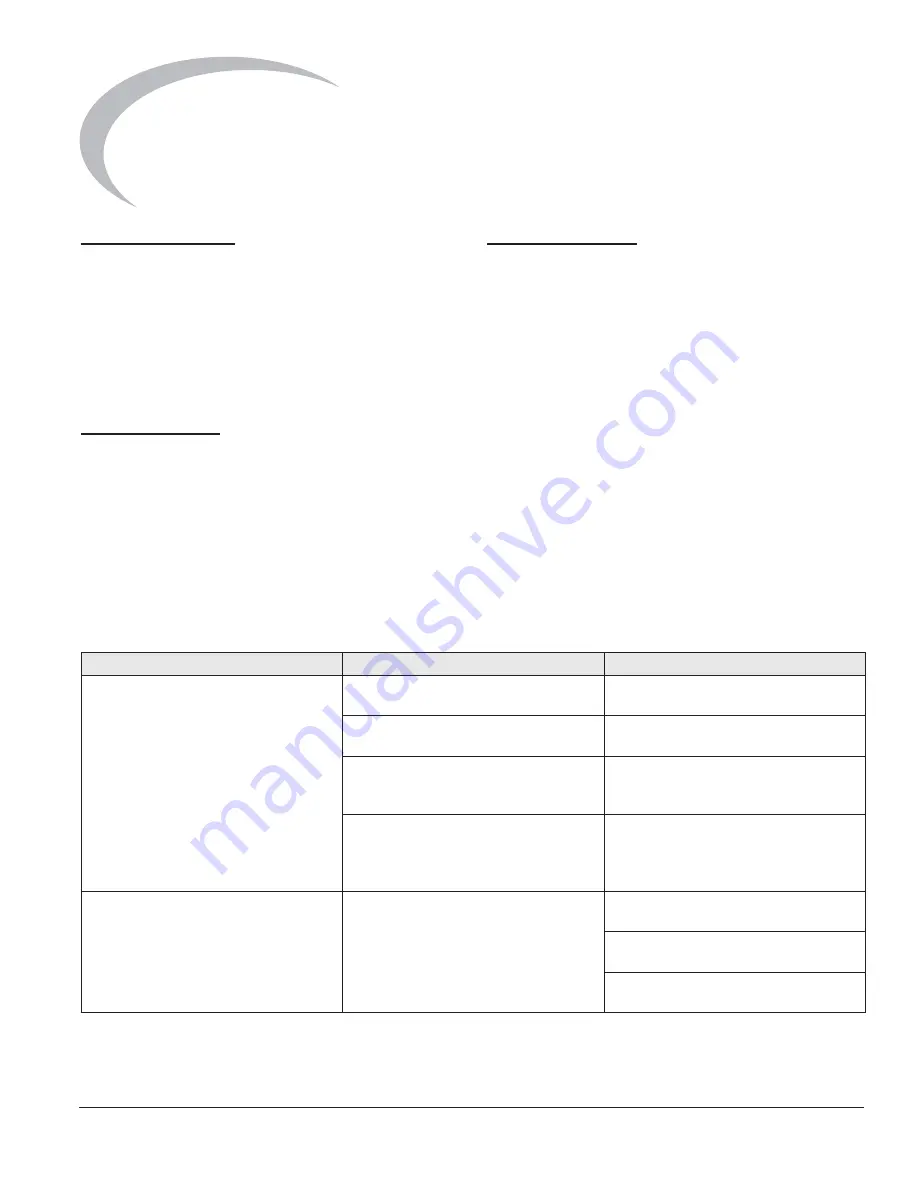

Problem

Possible Cause

Solution

No POWER ON light

Main supply power is off

Be sure main power to the system is

switched “on”.

Main disconnect switch is off

Turn the control panel main disconnect

switch on.

Loose connection

Check for voltage on panel terminals,

turn off main power and inspect,

tighten wire connection.

Blown fuse

Verify that all fuses are good and

properly installed. If blown, have a

qualified electrician determine the

cause and fix before replacing fuse.

Cannot initiate start sequence

Inlet low gas manual reset pressure

switch has activated

Check incoming gas pressure: adjust if

necessary.

Check pressure switch setting and

operation.

If used, check that the pressure switch

isolating valve is not closed.

6