KGL Operating Manual – VS 3010 BS

2018-07-02

/

24 178

4.4 Low-pressure Regulation

The low-pressure regulation has the task of maintaining the suction side pressure at a specified setpoint. The

controller provides two different methods for this regulation task:

Step controller

Regulation by loading and unloading compressor stages or compressor capacity stages

Combined control

Regulation using a speed-controlled compressor in combination with one or more fixed-speed

compressors

The setting of the setpoints for the temperature ranges Z1 and Z2 is dependent on the room temperature or

the refrigeration requirement (in conjunction with the E*LDS case controllers).

The actual value recording is performed using two

range) with continuous current output (4..20 mA) or voltage output (0..10 V).

4.4.1 Control algorithm for LP control

The control algorithm depends on the type of control.

In the wet vapour range, the temperature is a clear function of the pressure: t = f (p, refrigerant). The

controller calculates temperatures for the LP range from the recorded pressures. Temperature values

are used exclusively for the regulation. In the manual, temperatures (t /t ) represent pressures (p /p

0 c

0

c

).

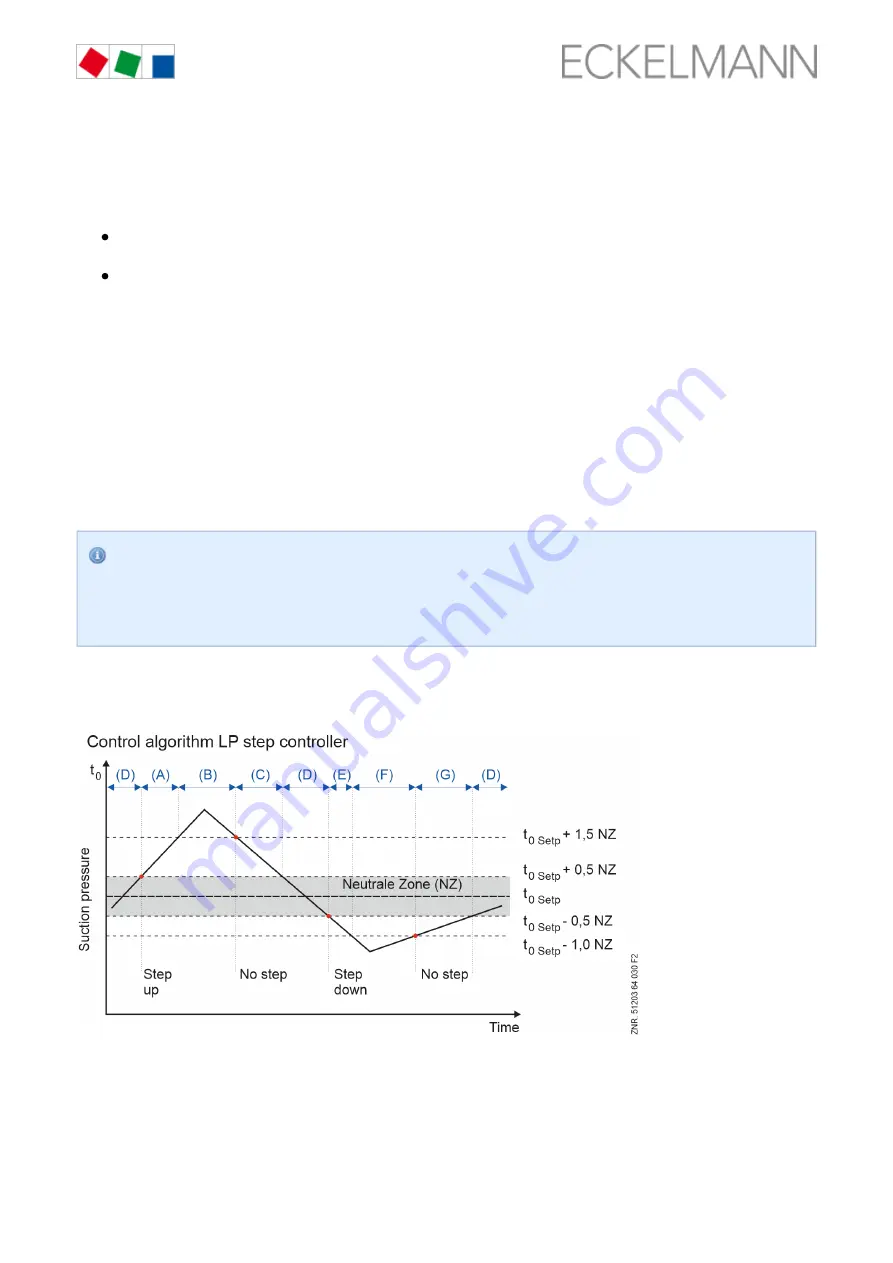

4.4.2 Control algorithm with LP step controller

The low-pressure measured by an A/D converter is compared with the setpoint:

(A) At a pressure greater than the setpoint plus 0.5 times the neutral zone (NZ) and less than the setpoint plus

1.5 times the NZ, the step switching mechanism loads stages in the event of a

pressure change.

positive

(B) At a pressure greater than the setpoint plus 1.5 times the NZ, the step switching mechanism loads stages

of the pressure change.

independently

(C) In the case of falling pressure that is less than the setpoint plus 1.5 times the NZ and is greater than the