Version 2.02 15.05.2007

Function of VS 3000

22

3.22 Monitoring cylinder head temperature

Compressor cylinder head temperature is monitored to keep it from exceeding a defined maximum so as to pre-

vent damage to the compressor. The maximum cylinder head temperature at which a compressor is disabled

and also the compressor enabling temperature are definable by the parameters

Comp. OFF temp

and

Comp.

ON temp

(Menu 3-4). The respective compressor is stopped after a definable time delay elapses (Menu 3-4

Comp. temp del.

) and disabled for all further control actions when temperature exceeds the set maximum.

The compressor remains disabled until temperature drops below the enabling level. If this action is repeated

several times in a single day (five actuations) and if more than one compressor is still available in the pack, the

compressor will be disabled permanently and must then be re-enabled manually (Menu 3-1-c

Enable

comp.stages

). This causes fault report

Auto disable Cx

to be generated.

Compressor fault with combined control

Compressor fault occurs in the following conditions:

- Actuation of motor overload cutout

- Actuation of low oil pressure cutout

- Cylinder head temperature rise above maximum allowable level

In occurrence of fault conditions on one of the compressors that can be allocated to the frequency changer

(Compressor 1 and 2), the compressor is stopped and fault report is generated as a function of the base load

rotation output state (Digital Output 10 of VS 3000).

Compressor fault with single-stage compressors

With variable-speed compressors the frequency changer is always enabled together with the first compressor

capacity stage. Either Compressor 1 or Compressor 2 can be allocated to the frequency changer by base load

rotation. If base load rotation has not taken place (base load rotation output OFF), a fault on Compressor 1

causes Capacity Stage 1 to be shut down and a corresponding fault report to be generated for Compressor 1.

A fault on Compressor 2 causes Capacity Stage 2 to be shut down and a corresponding fault report to be gener-

ated for Compressor 2.

Following base load rotation (base load rotation output ON)), a fault on Compressor 1 causes Capacity Stage 2

to be shut down and a corresponding fault report to be generated for Compressor 1.

A fault on Compressor 2 causes Capacity Stage 1 to be shut down and a corresponding fault report to be gener-

ated for Compressor 2.

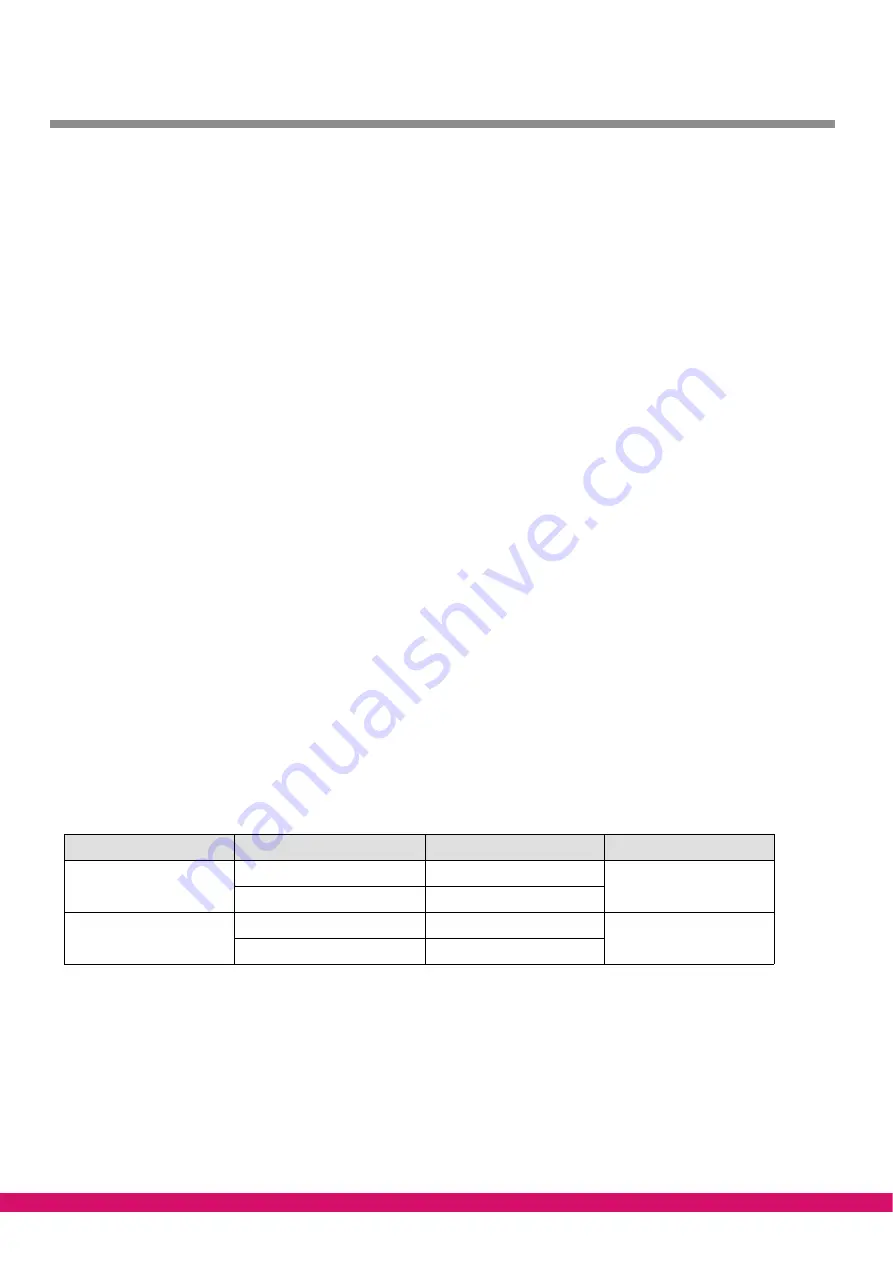

Fault

Base load rotation output

Capacity stage output OFF

Fault report

Compressor 1

ON

Stage 2

Compressor C1

OFF

Stage 1

Compressor 2

ON

Stage 1

Compressor C2

OFF

Stage 2

Compressor fault with capacity-controlled compressors

With multi-stage compressors operated in combined control, the frequency changer is always enabled together

with the first compressor relay stage and the motor of the first compressor is actuated. The following relay

stages are used to actuate the bypass valves of the first compressor.

With combined control the frequency changer can be assigned to either Compressor 1 or Compressor 2 by base

load rotation. This however requires the associate compressor capacity stages to also be rotated as well as the

compressor base load stage when base load rotation takes place.

If the base load is not changed (Base Load Rotation Output OFF), a fault on Compressor 1 will cause shutdown

of Capacity Stage 1 (frequency changer enable and Compressor C1 motor actuation) as well as Capacity Stage