PN 18280-00 R041306

26

SERVICE & MAINTENANCE

BEFORE INSPECTING OR SERvICING ANY PART OF ThIS MAChINE, ShuT OFF POWER SOuRCE,

DISENGAGE ThE hYDRAuLICS, OPEN ShIELD AND MAkE SuRE ALL MOvING PARTS hAvE COME TO A COMPLETE STOP.

WARNINg

5.7.2 REpLAcINg hYDRAuLIc DRIvE bELT

Check the condition of the drive belt annually or after every

25 hours of operation, whichever comes first. If the belt is

cracked, frayed, worn or stretched, replace it. Follow proce-

dure below to replace the drive belt.

using a wrench, pull the small idler pulley away from the

hydraulic belt to release the tension

Remove the hydraulic drive belt from the drive pulley on the

engine and the hydraulic pump

using a wrench, pull the small idler pulley towards the center

of the chipper

Install the hydraulic drive belt on the hydraulic pump, on out-

side of idler pulley and on engine drive pulley.(figure 5.6)

Release idler to apply tension on hydraulic pump drive

belt.

1.

2.

3.

4.

5.

6.

5.7.2 ADjusTINg DRIvE bELTs

Lower the engagement handle

Loosen bolt on engine tie. DO NOT REMOvE.

verify the belt tensioning bolts on the engine mount plate are

tight against the engine mount.

Loosen the four engine mount bolts.

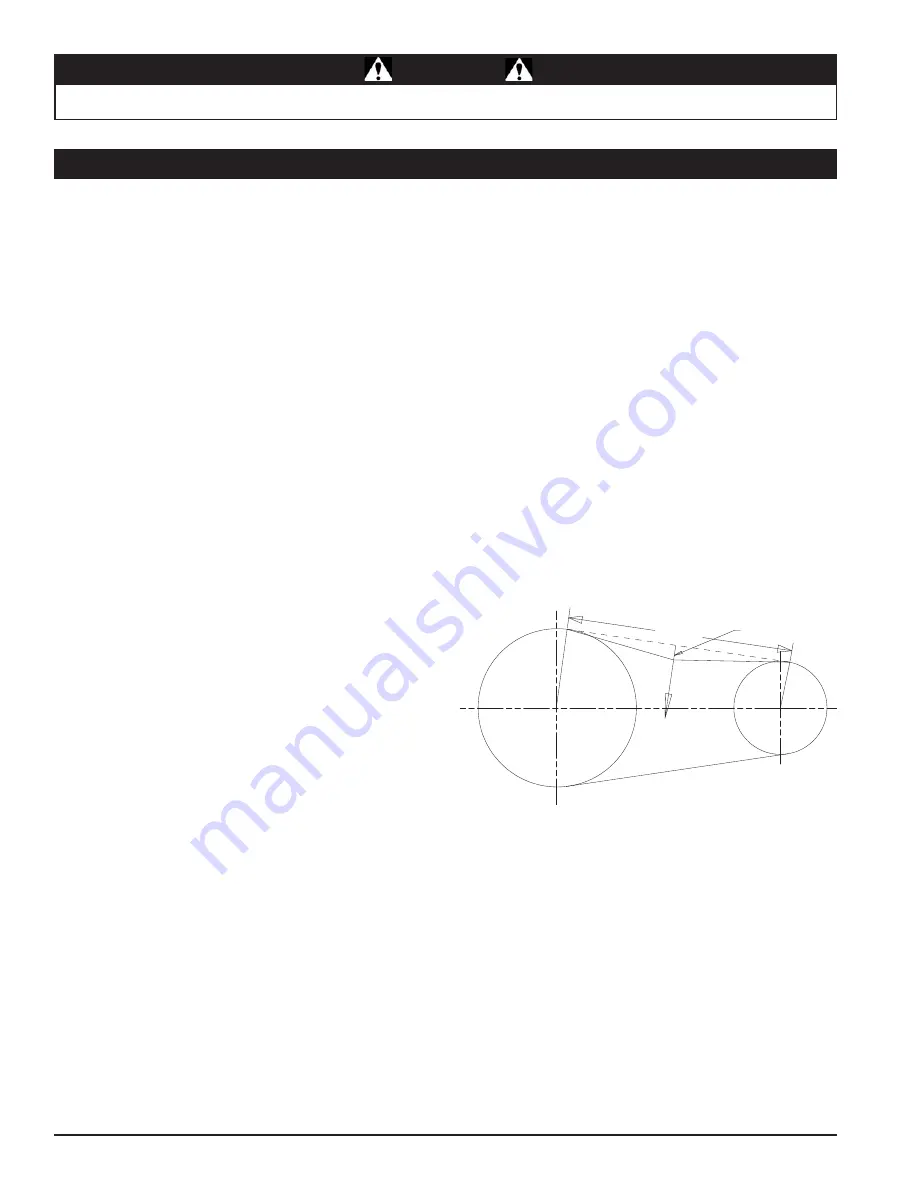

Alternately turn each of the belt tension bolts clockwise an

equal number of turns until the belt deflection at the center

of the belt is 7/16” when a 20 lb load is placed against the

belt (figure 5.5)

Check pulley alignment using a straight edge and adjust the

appropriate belt tension bolt if required.

Tighten the four engine mount bolts to the appropriate

torque

Tighten the engine tie bolt

Lift the engagement handle, start engine and lower engage-

ment handle to test units. Adjust pulleys and belt tension as

needed.

1.

2.

3.

4.

5.

6.

7.

8.

9.

Figure 5.5 - Drive Belt Tension

Span Length

Force

20 lbs

7/16" Deflection

5.7 DRIvE bELTs (coN'T)