Operating instructions

W2E143-AA15-01

Translation of the original operating instructions

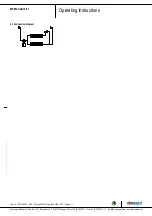

4.3 Connection diagram

Item no. 11120-5-9970 · ENU · Change 204653 · Approved 2020-01-07 · Page 8 / 11

ebm-papst Mulfingen GmbH & Co. KG · Bachmühle 2 · D-74673 Mulfingen · Phone +49 (0) 7938 81-0 · Fax +49 (0) 7938 81-110 · [email protected] · www.ebmpapst.com