Operating instructions

R3G630-AA12-13

Translation of the original operating instructions

3. TECHNICAL DATA

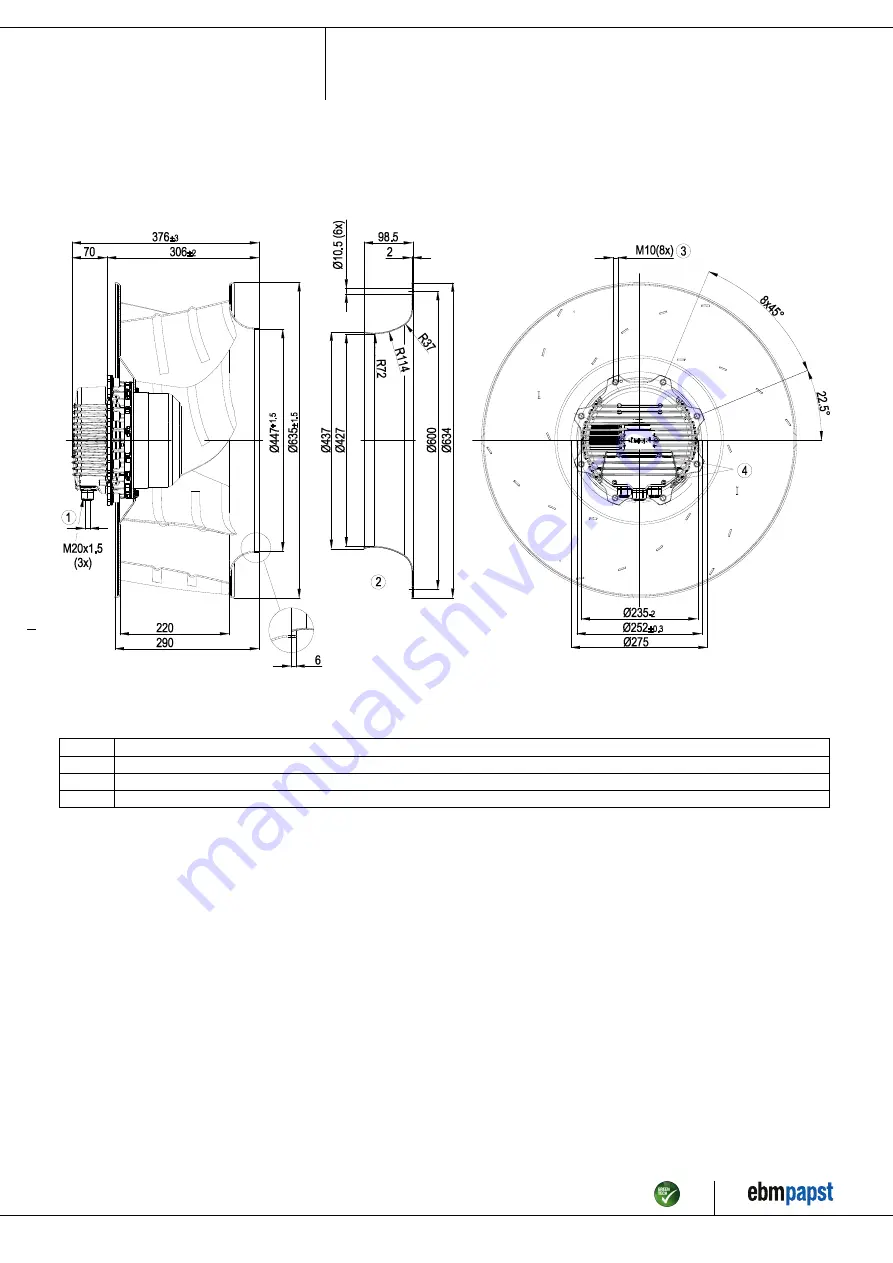

3.1 Product drawing

All measures have the unit mm.

1

Cable diameter: min. 4 mm, max. 10 mm, tightening torque: 4±0.6 Nm

2

Accessory part: inlet nozzle 63070-2-4013 not included in the standard scope of delivery; other inlet nozzles on request

3

Depth of screw max. 25 mm

4

Tightening torque 3.5±0.5 Nm

Item no. 50741-5-9970 · Revision 75933 · Release 2012-01-24 · Page 4 / 12

ebm-papst Mulfingen GmbH & Co. KG · Bachmühle 2 · D-74673 Mulfingen · Phone +49 (0) 7938 81-0 · Fax +49 (0) 7938 81-110 · [email protected] · www.ebmpapst.com