Operating instructions

K3G560-HE07-01

Translation of the original operating instructions

Motor protection

Reverse polarity and locked-rotor

protection

Protection class

I (with customer connection of protective

earth)

Conformity with

standards

EN 61800-5-1; CE; UKCA

Approval

EAC; UL 1004-7 + 60730-1; CSA

C22.2 No. 77 + CAN/CSA-E60730-1

With regard to cyclic speed loads, note that the rotating parts of

the device are designed for a maximum of one million load

cycles. If you have special questions, consult ebm-papst for

support.

;

Use the device in accordance with its degree of protection.

Information on surface quality

The surfaces of the products conform to the generally applicable industrial

standard. The surface quality may change during the production period.

This has no effect on strength, dimensional stability and dimensional

accuracy.

The color pigments in the paints used perceptibly react to UV light over

the course of time. The product is to be protected against UV radiation to

prevent the formation of patches and fading. Changes in color are not a

reason for complaint and are not covered by the warranty. UV radiation

in the frequency range and the intensity of natural solar radiation has no

effect on the technical properties of the products.

3.5 Mounting data

Further mounting data can be taken from the product drawing or Chapter

4.1 Mechanical connection as required.

Strength class of

screws

10.9

;

Secure the screws against unintentional loosening (e.g. use self-

locking screws).

3.6 Transport and storage conditions

Max. permitted

ambient temp. for

motor (transport/

storage)

+80 °C

Min. permitted

ambient temp. for

motor (transport/

storage)

-40 °C

3.7 Electromagnetic compatibility

EMC immunity to

interference

According to EN 61000-6-2 (industrial

environment)

EMC interference

emission

According to EN 61000-6-4 (industrial

environment)

If several devices are connected in parallel on the supply side

so that the line current of the arrangement is in the range 16 - 75

A, this arrangement conforms to IEC 61000-3-12, provided that

the short-circuit power S

sc at the connection point of the

customer system to the public power grid is greater than or

equal to 250 times the rated output of the arrangement. It is the

responsibility of the installation engineer or operator/owner of the

device to ensure, if necessary after consultation with the

network operator, that this device is only connected to a

connection point with an S

sc value greater than or equal to 250

times the rated output of the arrangement.

4. CONNECTION AND STARTUP

4.1 Mechanical connection

DANGER

Heavy and unwieldy device.

Crushing hazard

→ Do not grasp or transport the device by the fan impeller.

Move the device with a crane using ropes or cloth straps.

There are holes drilled in the support structure that can be

used for transport.

→ After installation, ensure that the blades on the fan

impeller are not deformed or bent.

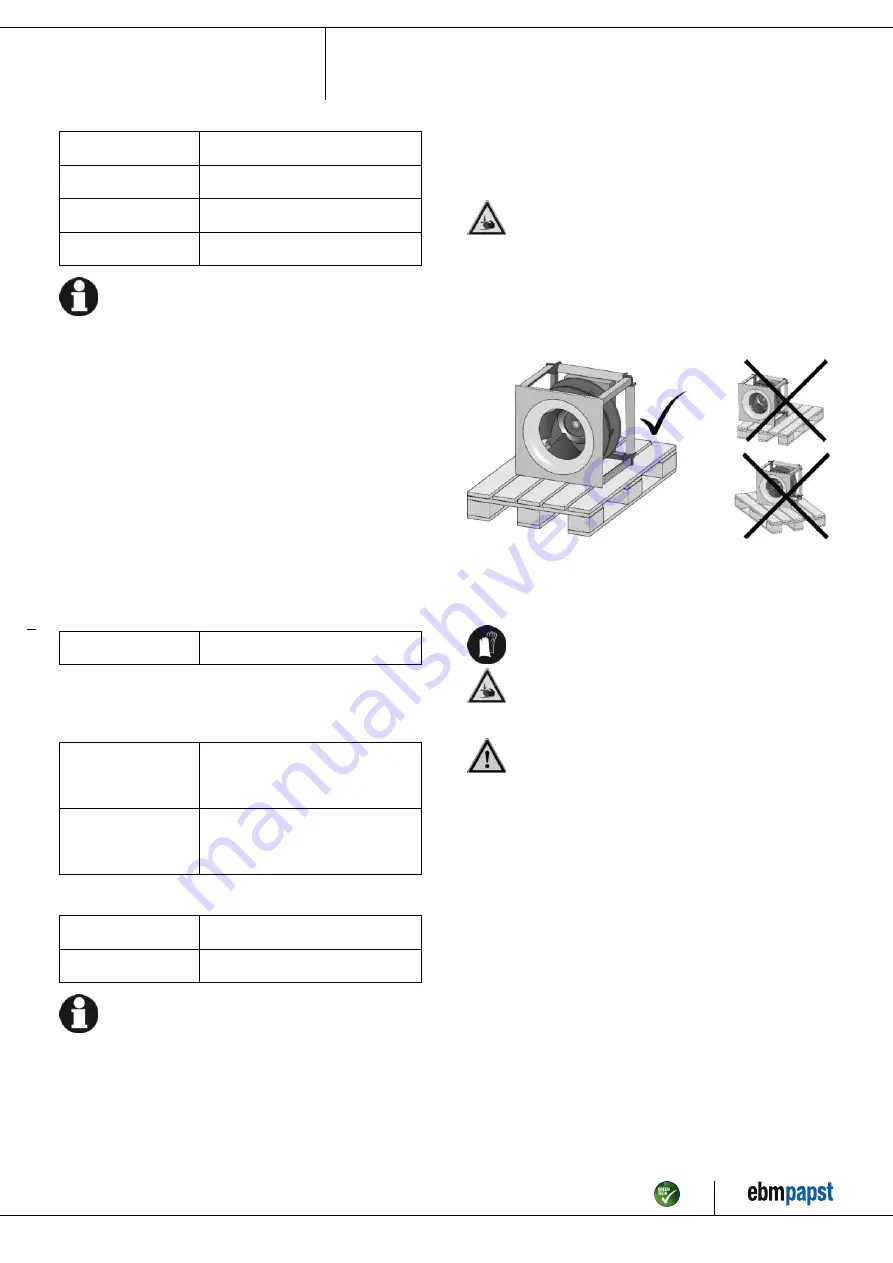

Fig. 1: Make sure the RadiPac fan is firmly secured when transporting

on a pallet. The impeller is not to be subjected to load. If the impeller is

subjected to load (e.g. during transportation), the fan could be severely

damaged!

CAUTION

Risk of cutting and crushing when removing device

from packaging

→ Carefully remove the device from the packaging by grasping

hold of the frame. Never subject to any impact.

→ Wear safety shoes and cut-resistant safety gloves.

CAUTION

Device weighs over 25 kg! Heavy load when unpacking

device.

Risk of physical injury, such as back injuries.

→ Use suitable hoisting equipment to remove the device from

its packaging.

;

The fan may not be handled in the area around the inlet nozzle during

transport and installation.

There is a risk of damage to the impeller.

;

Check the device for transport damage. Damaged devices are not to

be installed.

;

Install the undamaged device in accordance with your application.

4.1.1 Installation of RadiPac fan

Use is always to be made of appropriate hoisting equipment and a

suitable lifting device when transporting the RadiPac for installation

purposes. Use only suitable ropes or chains (see Chapter 3.4 Technical

description for product weight). To attach the hoisting equipment, use four

M10 eye bolts that can turn under load; screw the eye bolts into the

tapped holes provided. For fans not provided with tapped holes, use the

existing holes and lock the threaded bolts that can turn (M8 or M10) on

the underside with a nut. Do not use standard DIN 580 eye bolts. Note

that the angle between the ropes or chains may be between 0° and 60°.

During transportation, an acceleration of 2 g must not be exceeded.

Item no. 56858-5-9970 · ENU · Change 260717 · Approved 2022-06-23 · Page 6 / 13

ebm-papst Mulfingen GmbH & Co. KG · Bachmühle 2 · D-74673 Mulfingen · Phone +49 (0) 7938 81-0 · Fax +49 (0) 7938 81-110 · [email protected] · www.ebmpapst.com