,QVWUXFWLRQ0DQXDO

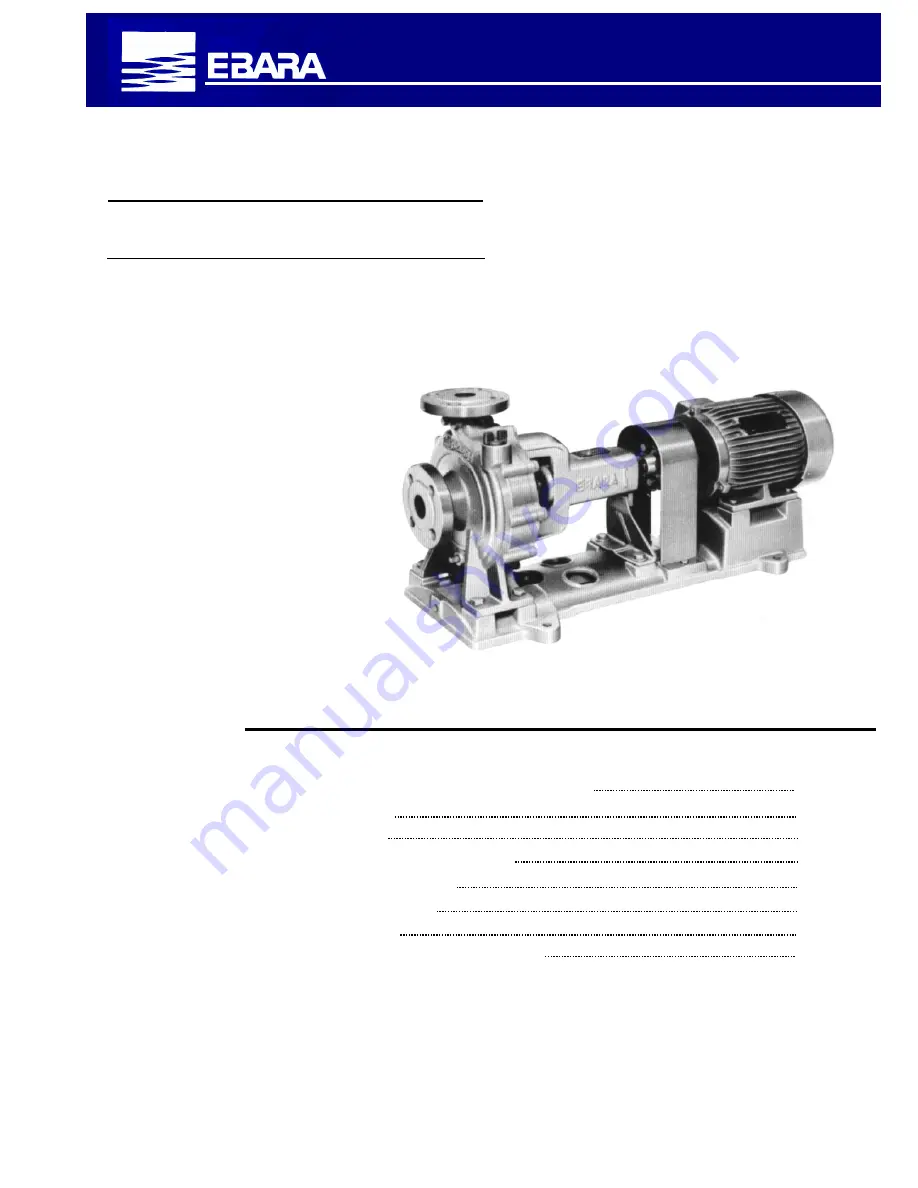

EBARA End Suction Volute Pump

MODEL

&RQWHQWV

1.

Safety Information and Introduction

1

2.

Installation

2

3.

Operation

4

4.

Maintenance and Service

5

5.

Replaceable Parts

6

6.

Troubleshooting

7

7.

Contruction

8

8.

Disassembly and Assembly

9

FS9003 506-R3

)6$

Section