Technical Data

TD534-0501002U

Instructions for the Installation,

Operation and Maintenance

of W-SLC-7.2

Effective January 2013

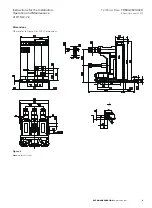

Figure 7

Figure 8

Figure 9

Figure 10

Figure 11

Figure 12

Supplied documents and accessories

• Product qualification certificate

• Factory inspection report

• Instruction Book

• Shipping document

• Schematic diagrams

Ordering information

When ordering, please notify:

• Product type numbers, style numbers and quantities

• For other special requests, please notify

Safety precautions

• Notice: Protect the vacuum interrupter from impact from external

objects. Please follow the instruction book for inspection before

putting into use. Only after it’s confirmed as qualified, the W-SLC

is ready for use.

• Before maintenance, do not conduct any maintenance work

when panels and secondary circles are live.

• Do not conduct maintenance when the contactor is closed.

• Make sure to remove all the tools before operating the unit.

• Lifting lugs shall be removed from the unit and should be stored

properly for back up use.

a) During circuit resistance testing, testing current should not

go through primary disconnect springs;

b) Do not loosen the parts sealed on the frame and

mechanisms. If required for adjustment, please ask trained

staff or manufacturer’s staff to carry out the procedure.

1. In order to prevent unexpected accidents, works such as

adding lubricants to operating mechanisms shall be conducted

with the contactor in the open position

2. Trouble shooting for the W-SLC should be performed by

trained staff or manufacturer’s service people, in order to make

proper adjustments

3. If users need to conduct parameter testing for the W-SLC,

please pay attention to following notices:

3. Use special tool (the part No. is 534-8161200) for assembling

fuse tube to remove movable fuse holder cover, see Figure 8;

4. Put on clean electrician gloves and remove the fuse, see Figure 9;

5. Check the sliding-connecting spring contact fingers on both

ends of fuse holder, to make sure that there is no abnormity or

deformation in the fuse holder. Then add a small amount of

conductive paste evenly on the inner side of each spring contact

finger (the side contacting the fuse), see Figure 10 and Figure 11;

6. Hold a new fuse in hand. Take care to notice that the striker pin

side is facing inwards. After center alignment is confirmed, push

it to the end at a constant speed in a horizontal direction;

7. Mount the head of fuse holder, and use special tool (the part No.

is 534-8161200) to assemble the fuse tube and to fasten the

movable fuse holder cover into position;

8. Mount screws to fasten the movable fuse holder cover and use

inner hexagon spanner to tighten;

9. Use the other end of the special tool (the No. is 534-8161200) to

measure the length by which the fuse is above the fuse unit

base, to make sure that the plane of upper arm is within the

notch range, see Figure 12;

10. Check for abnormity in spares and parts including primary

contact. Check any removed spares and parts which have not

mounted back;

11. Conduct again opening and closing operation tests, to

make sure that operating and interlocking work properly;

12. Rack into the panel once again. Use the cradle racking handle

to rack the W-SLC-7.2 to ‘Service’ position, to be ready for

operation.

Notice:

9

EATON CORPORATION

www.eaton.com