11

EATON Vane Motors M-2740-S June 2011

Service, Inspection and Maintenance

Service Tools

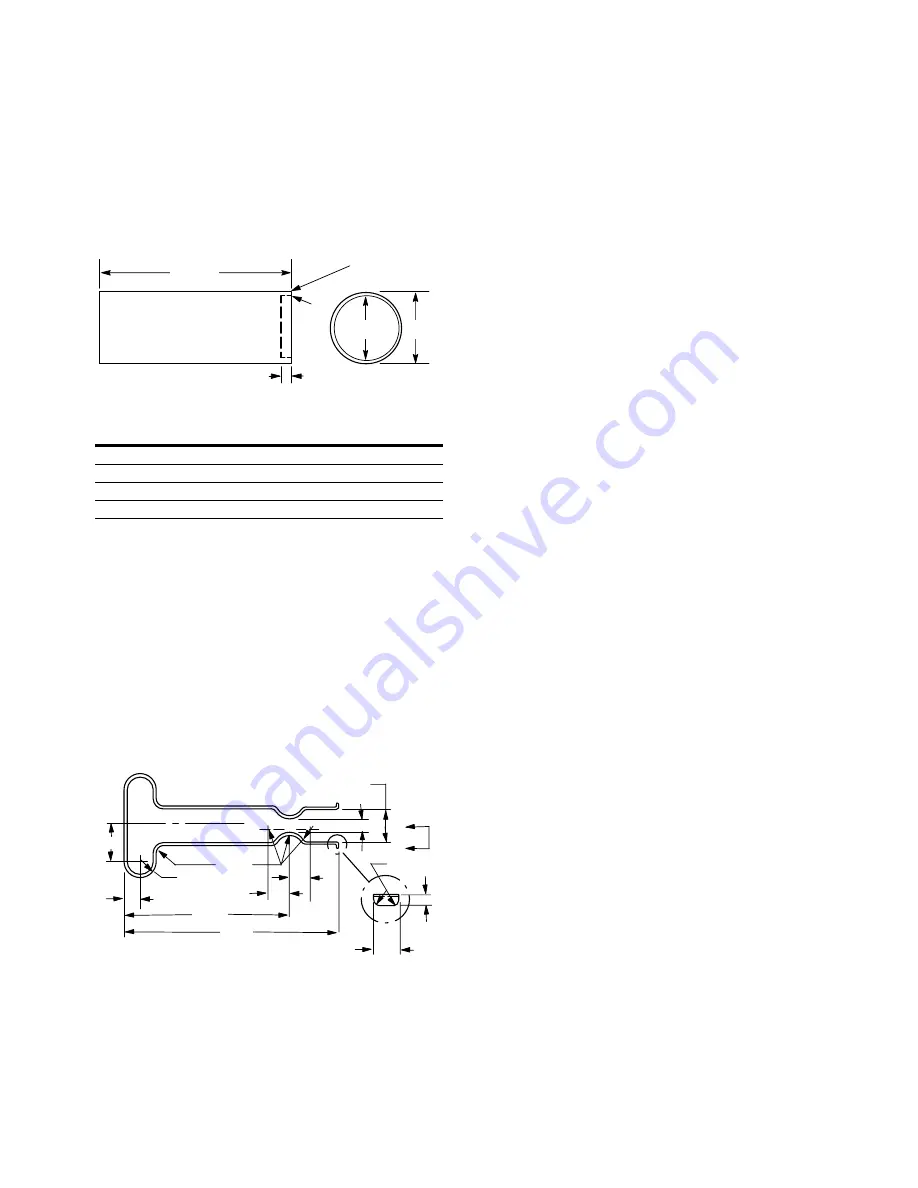

Special tools required for these units are shaft seal drivers

and adapter extractor tool. The seal drivers can be made from

round stock machined as shown in Figure 7.

The recess in the tool will be deep enough so uniform

pressure is applied to the recessed area in the seal channel

rather than on the seal lip. The outside diameter of the tool

will not interfere with the spring around the seal lip.

The adapter extractor tool is designed to remove the hub

adapter from the body after the cartridge is removed (see

Figure 8). The extractor tool engages between the ball

bearing and the hub adapter.

Inspection

Periodic inspection of oil condition and tubing connections

can save time-consuming breakdowns and unnecessary parts

replacement. The following should be checked regularly.

1. All hydraulic connections must be kept tight. A loose

connection in a pressure line will permit the fluid to

leak out. Loose connections in other lines can permit air

to be drawn into the system, resulting in noisy and/or

erratic operation.

2. Clean fluid is the best insurance for long service life.

Therefore, the reservoir should be checked periodically

for dirt or other contaminants. If the fluid becomes

contaminated, the system should be thoroughly drained

and the reservoir cleaned before new fluid is added.

3. Filter elements also should be checked and replaced

periodically. A clogged filter element results in a higher

pressure drop. This can force particles through the filter

which would ordinarily be trapped, or can cause the

bypass to open, resulting in a partial or complete loss of

filtration.

4. Air bubbles in the reservoir can ruin the motor and other

components. If bubbles are seen, locate the source of the

air and seal the leak.

Adding Fluid To The System

When hydraulic fluid is added to replenish the system, it

should always be poured through a fine wire screen (200

mesh or finer).

It is important that the fluid be clean and free of any

substance which could cause improper operation or wear

of the motor or other hydraulic units. Therefore, the use of

cloth to strain the fluid should be avoided to prevent lint from

getting into the system.

Lubrication and Adjustments

Internal lubrication is provided by system oil flow. No periodic

adjustments are required, other than to maintain proper shaft

alignment with the driving medium.

Replacement Parts

Reliable operation throughout the specified operating range is

assured only if genuine Vickers parts are used. Part numbers

are shown in the parts drawings listed in Table 1.

Product Life

The longevity of these products is dependent upon

environment, duty cycle, operating parameters and system

cleanliness. Since these parameters vary from application to

application, the ultimate user must determine and establish

the periodic maintenance required to maximize life and

detect potential component failure.

Troubleshooting

Table 5 lists the common difficulties experienced with vane

motors and hydraulic systems. It also indicates the probable

causes and remedies for each of the troubles listed.

It should always be remembered that many apparent motor

failures are actually due to the failure of other parts of the

system. The cause of improper operation is best diagnosed

with adequate testing equipment and a thorough understand-

ing of the complete hydraulic system.

5.000

A

C

B

Radius Blend

Figure 7.

Figure 8.

Z

Z

.12R

1.38

.63

.19

.38

8.50

6.56

.63

.81

Adapter Extractor Tool

(14 gauge – SAE 1040 stock)

.50 R

.56 R

.81

1.00

5.000

A

C

B

Radius Blend

Figure 7.

Figure 8.

Z

Z

.12R

1.38

.63

.19

.38

8.50

6.56

.63

.81

Adapter Extractor Tool

(14 gauge – SAE 1040 stock)

.50 R

.56 R

.81

1.00

Dimension

Motor Size

A

B

C

25M-20

.312 1.375 1.468

35M-20

.312 1.687 1.781

45M-20

.437 1.906 2.218

50M-20

.437 2.166 2.348

NOTE: All dimensions in inches