Introduction

1-2

Eaton

®

Power Xpert

®

9395C UPS Installation and Operation Manual P-164000821—Rev 01

www.eaton.com/powerquality

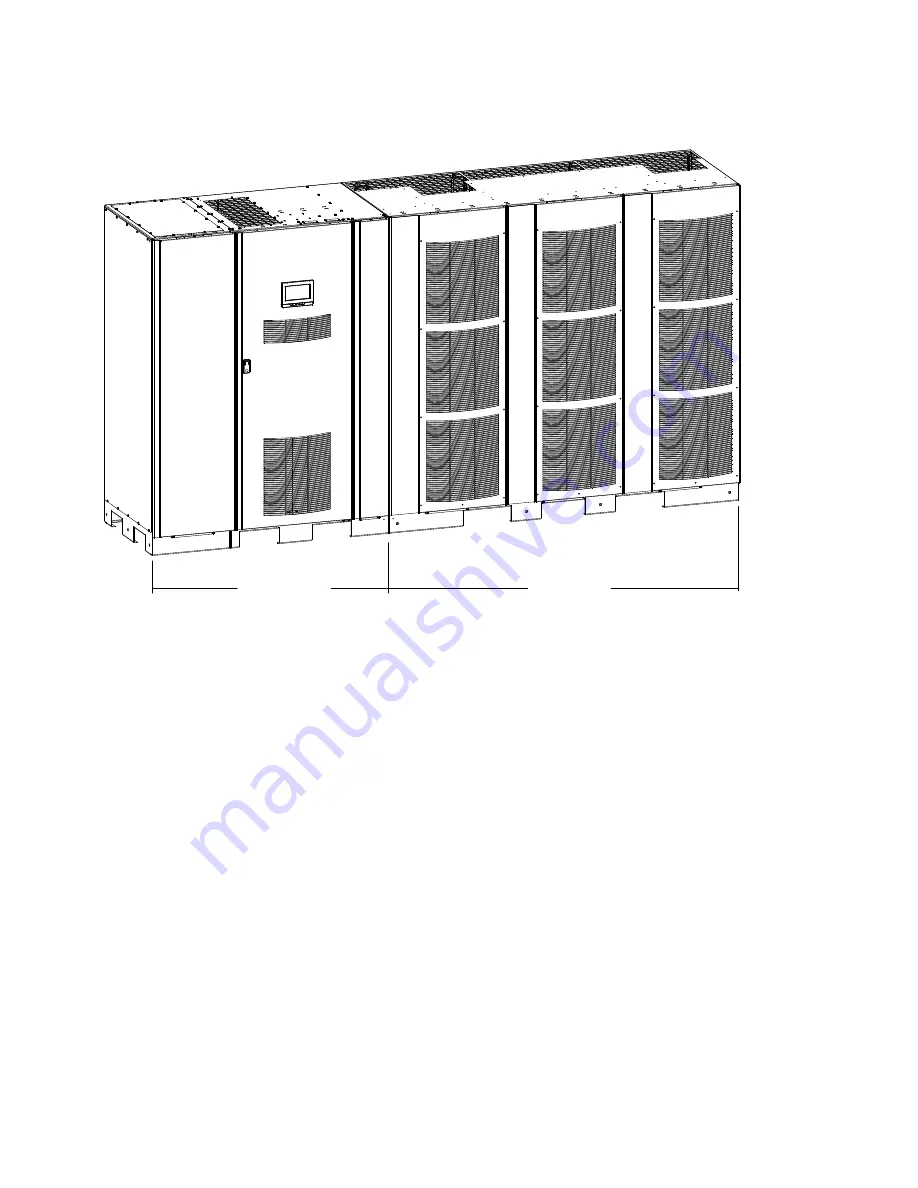

Figure 1-1. Eaton 9395C-1100 UPS

1.1

UPS Standard Features

The UPS has many standard features that provide cost-effective and consistently reliable power protection. The

descriptions in this section provide a brief overview of the UPS standard features.

1.1.1

Installation Features

Each UPS section is shipped separately. The sections are mechanically and electrically joined at the installation

site, and can be permanently bolted to the floor.

Power wiring can be routed through the top or bottom of the cabinet with connections made to easily

accessible terminals. Control wiring is routed through the top of the cabinet and must be installed in accordance

with Class 1 wiring methods.

1.1.2

Control Panel

The control panel, located on the front of the UPS is a 7-inch color touchscreen to control the operation of the

UPS and to display the status of the UPS system. See Chapter 7, “UPS Operating Instructions” for additional

information.

1.1.3

Customer Interface

l

Building Alarm Monitoring

. Up to five inputs in the UPS are available to connect the facility's alarm system

contacts. Some system configurations may limit the number of inputs available. The UPS uses these inputs

to monitor the building alarms in addition to the UPS status. See Chapter 8, “Communication” for additional

information.

PM SECTION

ISBM SECTION

Summary of Contents for Power Xpert Series

Page 2: ......

Page 23: ...Section I Installation...

Page 24: ......

Page 93: ...Section II Operation...

Page 94: ......

Page 155: ......

Page 156: ...P 164000821 1 P 164000821 1...