MADE IN U.S.A PAGE 2

PUBLICATION NO.

17228

9.

Be sure there is some spring pressure tending to

separate the two armatures “D” and “F”. This can

be tested by turning nut “G” clockwise. If nut “G”

cannot be turned, the gland inside is tight against

the stop on the screw and a maximum spring

pressure is applied.

10.

Turn the screw “C” on the top of the inner shoe

lever counter-clockwise to move the wedge

downward until the inner armature “D” sounding

pin “E” is flush when pressed. Tighten locknut “T”.

Readjust after wheel has reached normal

operating temperature to allow for thermal

expansion of the brake wheel. Re-inspect and

adjust if necessary after several operations.

11.

Tighten the pull rod nut “P” until the outer armature

“F” sounding pin “E” is flush when pressed. Tighten

locknut “U”. Readjust after wheel has reached

normal operating temperature to allow for thermal

expansion of the brake wheel. Re-inspect and

adjust if necessary after several operations.

12.

Full torque is obtained by turning the torque

adjuster “G” until the gland inside is snug against

the stop. Less than full torque is obtained by

turning the torque adjuster “G” counter-clockwise.

Check the nameplate on the brake and the table in

paragraph 14 for maximum torque setting for the

duty rating of the brake.

13.

With the brake set, tighten screws “K” on the shoes.

14.

Note that when the brake is correctly adjusted for proper

stroke, the torque adjuster washer face stands clear of the

armature “F” surface. As the lining wears this clearance

decreases. If the adjustment is neglected, the brake

operation can become sluggish and when the torque

adjuster washer touches the armature, the torque drops

rapidly reaching zero when the flexure of the lever is used

up. The clearance dimension is not a measurable value

but is determined by proper adjustment of individual

brakes.

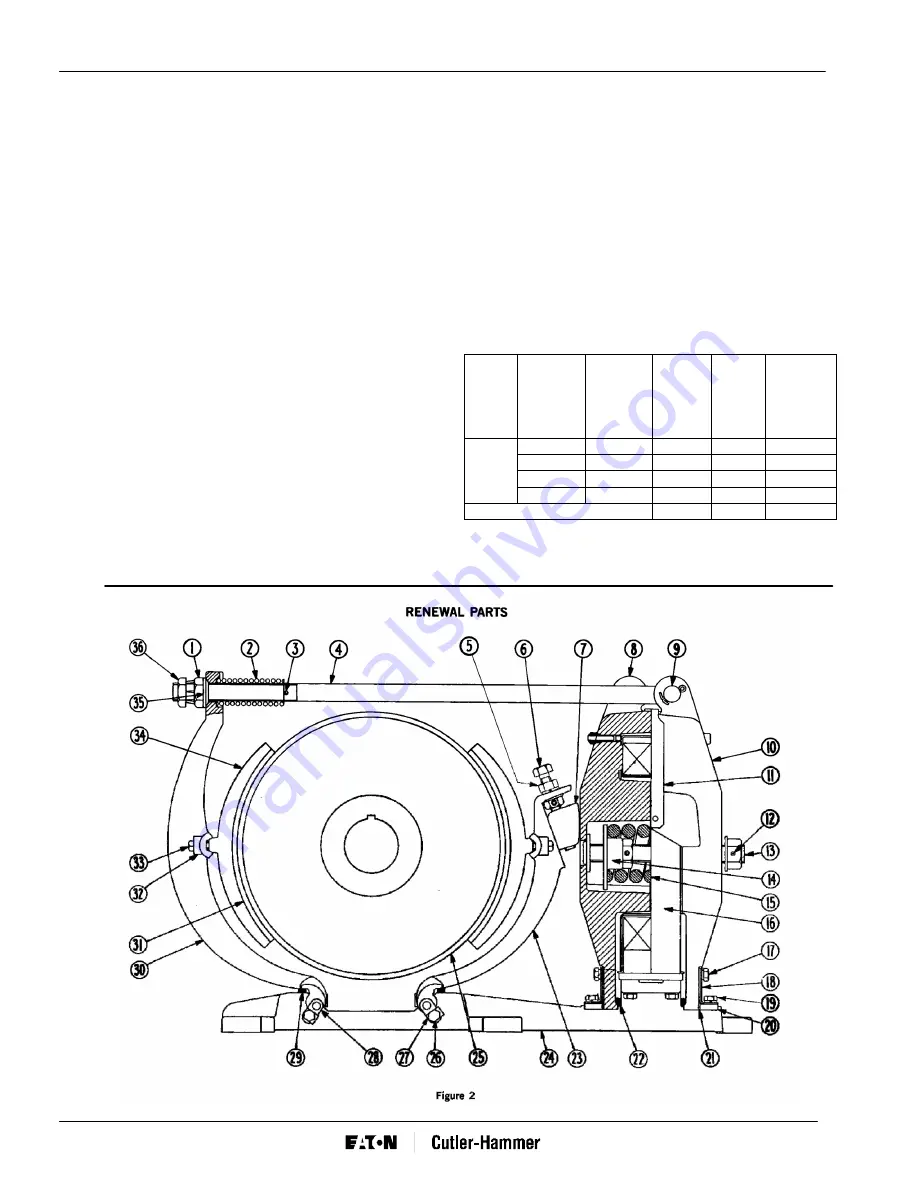

TORQUE ADJUSTMENT

Size

Of

Brake

Coil

Winding

Duty

Rated

Torque

Turn

“G”

Clock

wise

To

Solid

Back Off

Turns If

“G” From

Solid

Shunt

Int.

4000

X

0

Shunt

Int.

3000

X

1-5/6

Series

½ Hour

4000

X

0

23”

Series

1 Hour

2600

X

2-3/6

Minimum Torque

1000

X

3-4/6

PROCEDURE FOR INSTALLATION AND OPERATION – (Continued)