SPI9000 Inverter Unit FI9 – FI14 User Manual

2-6

For more information visit:

www.EatonElectrical.com

MN04004002E

September 2006

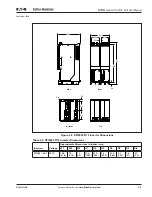

Table 2-5: Mounting Space Requirements

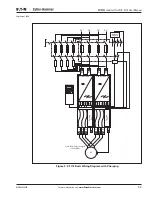

Table 2-6: Required Cooling Air

Power Losses

Raising the switching frequency of the drive, to reduce motor noise for example, inevitably

affects the power losses and cooling requirements. For more information, contact Eaton.

Frame

Voltage

Approximate Dimensions in Inches (mm)

A

B

B

2

C

FI9

380 – 500V

525 – 690V

7.9 (200)

.79 (20)

3.9 (100)

FI10

380 – 500V

525 – 690V

7.9 (200)

.79 (20)

3.9 (100)

FI12

380 – 500V

525 – 690V

7.9 (200)

.79 (20)

0

3.9 (100)

FI13

380 – 500V

525 – 690V

7.9 (200)

.79 (20)

0

3.9 (100)

FI14

380 – 500V

525 – 690V

7.9 (200)

.79 (20)

0

3.9 (100)

A = free space above the inverter

B = distance between inverter and cabinet wall

B

2

= distance between two inverters

C = free space underneath of the inverter

Frame

Voltage

Greatest Possible

Heat Loss (kW)

Cooling Air

Required (cfm)

Minimum Air

Exhausting Hole

on Switchgear (in

2

)

FI9

380 – 500V

525 – 690V

4.8

4.6

677

77.5

FI10

380 – 500V

525 – 690V

8.3

9.1

824

93

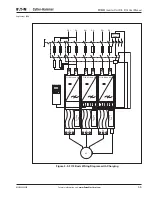

FI12

380 – 500V

525 – 690V

16.5

18.0

1648

186

FI13

380 – 500V

525 – 690V

23.0

26.0

2472

279

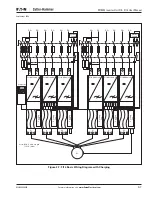

FI14

380 – 500V

525 – 690V

46.0

52.0

2 x 2472

2 x 279