8.

To make the final horizontal (radial) adjustment, loosen the four (4) slipfitter

base bolts.

9.

Rotate the floodlight housing to the desired position.

10. Tighten the slipfitter base bolts to 19 lbs.-ft. to lock in position.

11. Turn power on.

LAMP INSTALLATION AND REPLACEMENT

1.

Note both vertical and radial aiming angles. If these are disturbed during

relamping, they should be readjusted after relamping.

2.

Disconnect power to the floodlight and allow to cool completely. Allow the

capacitor to discharge for 15 minutes.

3.

Completely loosen the twelve (12) captive cover screws and swing open the

cover. See Figure 4.

4.

Remove lamp.

5.

Perform cleaning and inspection as noted in the MAINTENANCE section.

6.

Screw new lamp into lampholder and securely tighten lamp. New lamp must

be identical type, size, and wattage as marked on the floodlight nameplate.

7.

Thoroughly clean lens and cover gasket seal with a clean, damp cloth. If this

is not sufficient, use a mild soap or a liquid cleaner such as Collinite NCF or

Duco #7. Do not use an abrasive, strong alkaline, or acid cleaner. Damage

may result.

8.

Close floodlight cover door making sure that all wires are safely inside and

positioned away from the ballast area. Securely tighten all cover screws. For

proper gasket seal, torque the cover screws to 22 lbs.-in.

MAINTENANCE

Perform visual, electrical, and mechanical inspections on a regular basis. This

should be determined by the environment and frequency of use. However, it

is recommended that checks be made at least once a year. We recommend

an Electrical Preventive Maintenance Program as described in the National Fire

Protection Association Bulletin NFPA No. 70B. The lens should be cleaned

periodically to ensure continued lighting performance. To clean, wipe the lens with

a clean, damp, soft cloth. If this is not sufficient, use a mild soap or a liquid cleaner

such as Collinite NCF or Duco #7. DO NOT use an abrasive, strong alkaline or acid

cleaner.

•

Relamp high pressure sodium fixtures as soon as possible after the lamp

burns out to prevent damage to the ballast.

•

Visually check for undue heating evidenced by discoloration of wires or other

components, damaged parts, or leakage evidenced by water or corrosion

in the interior. Replace all damaged or malfunctioning components before

putting the fixture back into service.

•

Electrically check to make sure that all connections are clean and tight.

•

Mechanically check that all parts are properly assembled.

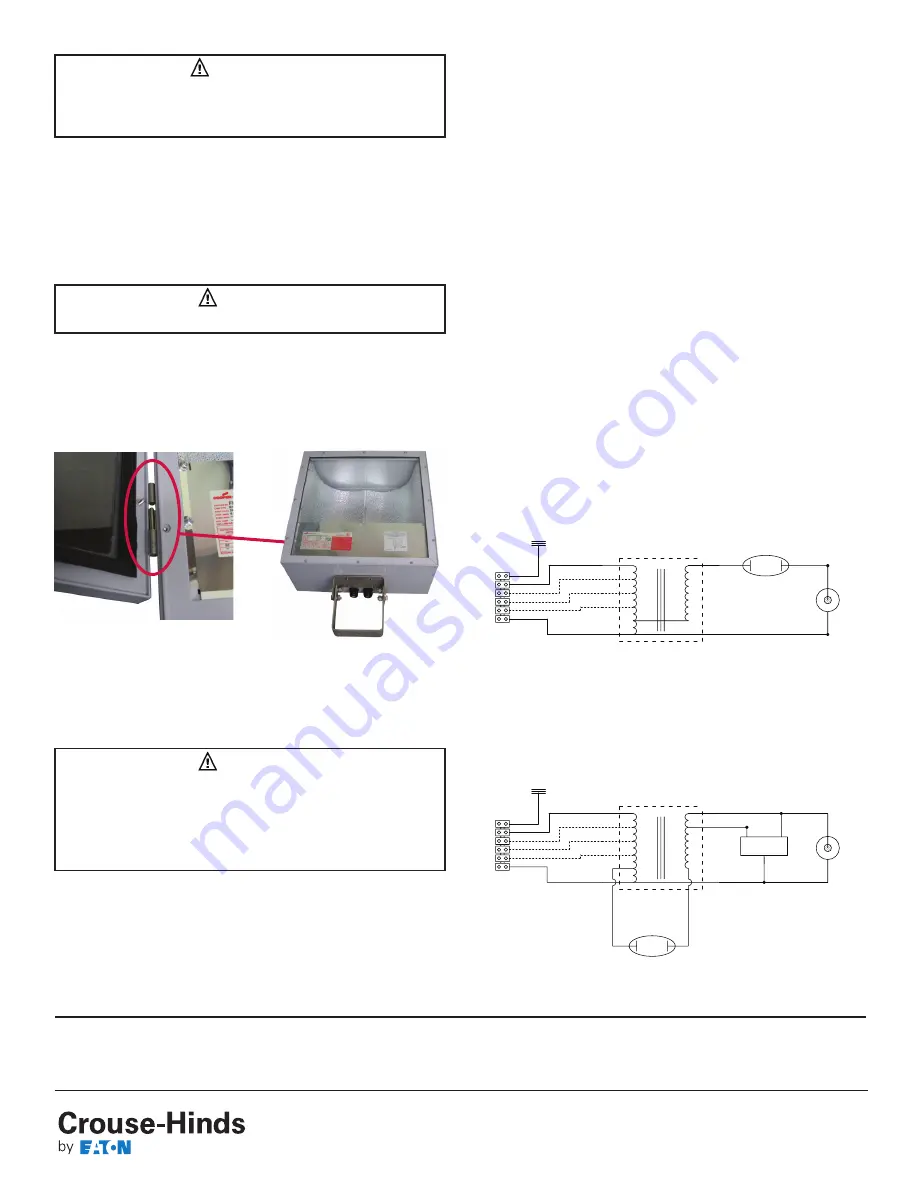

WIRING DIAGRAMS

WARNING

To avoid ignition of the hazardous atmospheres or overheating of the

floodlight:

Do not position the floodlight beyond the aiming range limits.

Figure 4 - Swing Open Cover with Lift-Off Door

CAUTION

To prevent ballast damage on high pressure sodium floodlights,

replace

burned out lamps as soon as possible.

To avoid shortened lamp life, lampholder failure, wiring faults, or

ballast failure,

tighten lamp firmly and completely.

To avoid injury,

guard against lamp breakage.

WARNING

Luminaire must be de-energized during lamp installation and replacement.

All statements, technical information and recommendations contained herein are based on information and tests we believe to be reliable. The

accuracy or completeness thereof are not guaranteed. In accordance with Crouse-Hinds “Terms and Conditions of Sale,” and since conditions of use

are outside our control, the purchaser should determine the suitability of the product for the intended use and assumes all risk and liability whatsoever

in connection therewith.

Eaton’s Crouse-Hinds Business

IF 1515

1201 Wolf Street Syracuse, New York 13208

Revision 5

Copyright © 2014

Revised 10/14

Supersedes 08/99

TERMINAL

BLOCK

LINE V

COM

LINE V

BALLAST

LINE V

LINE V

COM

LAMP

GRN

CAP

X1

X3

IGNITOR

X2

WHT

LAMP

BLK

HIGH PRESSURE SODIUM (HPS)

LINE V

COM

LINE V

BALLAST

LINE V

LINE V

COM

LAMP

METAL HALIDE (MH)

TERMINAL

BLOCK

GRN

CAP

WHT

LAMP

BLK

PULSE START METAL HALIDE (MH)