IOM 2596 Cast 10”–16” | Fabricated 10”-36” 10/2011

REV A.

Page 9 of 15

Eaton Filtration, LLC, 44 Apple Street, Tinton Falls, NJ 07724 | www.eaton.com/filtration | Phone: 732-212-4700

Installation, Operation & Maintenance Manual

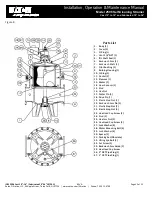

Model 2596 Self-Cleaning Strainer

Cast 10” to 16” and Fabricated 10” to 36”

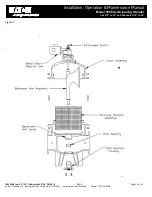

TROUBLE

SHOOTING

High Differential Pressure

1.

High solids loading in process fluid

A.

Increase length of backwash cycle.

B.

Backwash continuously.

2.

Piping

A.

Shorten backwash line, eliminate elbows, upward

pipe runs, restrictions due to valves, etc.

3. Backwash arm not rotating

A. Motor overloads tripped

1.

Obstruction between straining element and

backwash arm.

2.

Packing too tight.

3.

Bearing failure.

B. Motor/Reducer Failure

1.

Incorrect power applied to strainer motor.

2.

Overload heaters in motor starter improperly sized.

3.

Lubricant level in reducer too low.

4.

Reducer vent plugged.

4. Control problems

A.

Blown fuses.

B.

Incorrect power applied to control panel and/or

valves, switches, etc. I

C.

Incorrect wiring between control panel and valves,

switches, alarms, etc.

D.

Differential pressure switch improperly adjusted.

E.

Insufficient air pressure applied to pneumatically

operated backwash valves.

RECOMMENDED

SPARE

PARTS

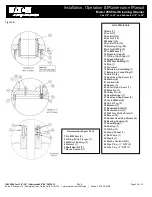

Qty.

Description

1

1

1

2

1

1

O-Ring (Cover Seal)

Shaft Seal Kit

Pilot Bushing

Pin (B/W Arm Drive Pin)

Straining Element Assembly (with gaskets)

O-Ring (Bottom Bushing Housing)

(Cast Strainers Only)

When ordering spare parts, be sure to specify all nameplate

data as well as description and quantity of parts.