Description and Installation

EPT033612 Issue 2 March 2018

2-43

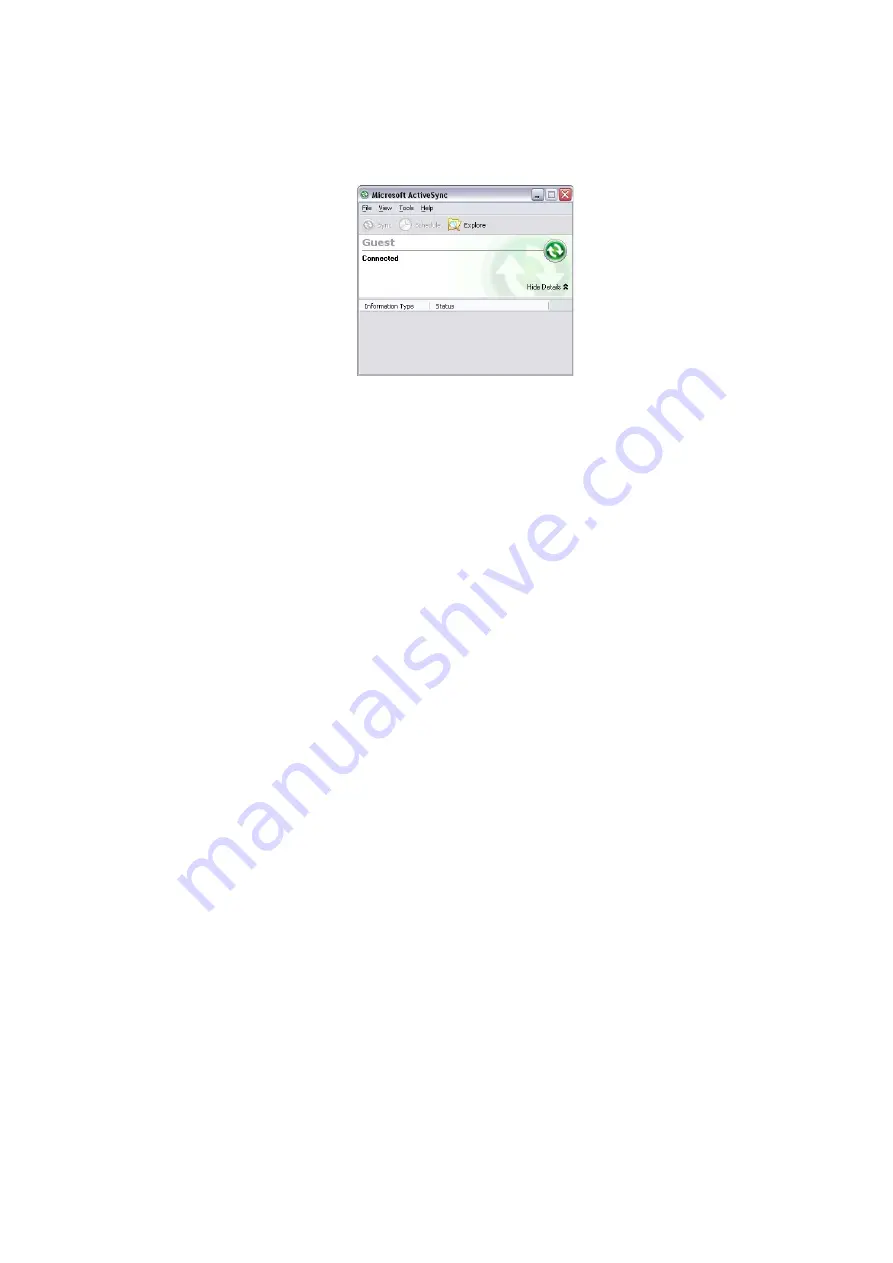

• Windows Mobile Device Center (or ActiveSync in Windows XP) should

now activate:

• To explore the device, select

Explore

.

If the program does not start, remove the mini USB cable and reinsert it.

Use of USB to Find Out which IP the Printer is

Using

(1) Navigate to the root folder of the device.

(2) If the printer software has started, a file named ‘IP_Address.txt’

should be there (press refresh once, as the folder is sometimes not

updated).

(3) Copy the ‘IP_Address.txt’ file to the PC’s hard drive.

(4) Use Notepad to open the ‘IP_Address.txt’ file now located on the PC.

(5) The file shows the IP address that was used during the last

connection.

(6) Remove USB cable if no further connection is required.

Change IP Address of Printer Using USB

(1) Navigate by using Explorer in ActiveSync to the ‘\Flash Disk’ folder of

the device.

(2) Copy the file ‘IpSetup.ini’ to the PC’s hard drive.

(3) Edit the file (using Notepad on the PC) to your requirements (the file

should be self explanatory). See the following image, where the text

box at the bottom shows a manual IP set-up:

Summary of Contents for Compact CM

Page 1: ...Compact CM Compact IM Easyprint Product Manual ...

Page 2: ... 2 EPT033612 Issue 2 March 2018 THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 10: ...Health and Safety 1 2 EPT033612 Issue 2 March 2018 THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 70: ...Operation 3 4 EPT033612 Issue 2 March 2018 THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 113: ...Operation EPT033612 Issue 2 March 2018 3 47 Line Movement IM Static ...

Page 126: ...Operation 3 60 EPT033612 Issue 2 March 2018 THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 129: ...Maintenance Service and Fault Finding EPT033612 Issue 2 March 2018 4 3 ...

Page 188: ...Technical Reference 5 2 EPT033612 Issue 2 March 2018 THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 193: ...EPT033612 Issue 2 March 2018 6 1 PART 6 Glossary of Terms CONTENTS Page GLOSSARY OF TERMS 6 3 ...

Page 194: ...Glossary of Terms 6 2 EPT033612 Issue 2 March 2018 THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 198: ...Glossary of Terms 6 6 EPT033612 Issue 2 March 2018 THIS PAGE INTENTIONALLY LEFT BLANK ...