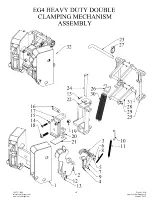

CLAMPING HEAD OR ATTACHMENT

PREVENTATIVE MAINTENANCE EXCHANGE & REFURBISHMENT PROGRAM

This service is designed to provide customers with an easy to use preventative maintenance

& refurbishment program to achieve the best performance and maximum service life.

The

clamping mechanism(s) should have regular preventative maintenance service in addition to

required visual inspections, belt replacement, and monthly lubrication. The intervals

between

services are dependent upon usage, but should generally be done at least once every year.

Loaner clamping head(s) or full attachment are provided free of charge however the

customer is responsible for all shipping costs incurred. Loaner attachments and clamping

mechanisms are finished in a different color to ensure identification as loaner units.

HOW IT WORKS:

•

Contact Easy Lift Equipment or your local dealer to obtain a return authorization number

for your clamping head(s) or full attachment. If needed a loaner clamping head(s) or

attachment will be shipped to your site to minimize down time while your equipment is

being serviced

•

Clamping head(s) only: remove the clamping head assembly from mast by removing the

circle cotter clip from the adjustment pin and pulling the adjustment pin out. Slide the

entire clamping head assembly up and out of the mast and reinsert the adjustment pin and

circle cotter pin.

•

Ship the original clamping head(s) or full attachment to Easy Lift Equipment in the same

box, container, or pallet that the loaner was received. Be sure to display the return

authorization number and company name on the outside of the box, container, or pallet.

•

The clamping head(s) or full attachment will be disassembled and assessed so a

maintenance quote can be provided for approval. Costs are determined by the required

parts, labor, and requested services or additional features.

SCOPE OF WORK TO BE PERFORMED:

Clean and lubricate all necessary pins.

(Sandblasting, welding, and re-powder coating is available upon request).

Replace

springs, jaws, cotter pins, or any worn parts.

Reassemble clamping head(s) or full

attachment.

•

Upon completion and approval, the clamping head(s) or full attachment will be returned

to the customer. The loaner clamping mechanism or attachment should be promptly

returned to Easy Lift Equipment.

The customer is responsible for all charges including but not limited to:

1. Parts & labor required for refurbishment or preventative maintenance.

2. Shipping to and from the company’s location.

3. Loss, damage, or repair(s) to the loaner equipment.

Should you have any questions regarding this progam, please call customer service at

800-233-1800 ext. 3, or your local dealer for clarification.

77