SCALE EQUIPPED MODELS (GRIP & WEIGH ATTACHMENTS)

If your equipment has a scale system, the indicator has already been calibrated and tested

before leaving the factory. It has been disconnected and packaged separately for safe travel.

Unpack the indicator from the box and mount to the unit on the provided bracket. Connect the

indicator cable to the unit cable by screwing the male and female ends together. Turn on the

indicator and ensure it reads zero before engaging a drum. If handling liquids in a drum, it may

take up to one minute for the indicator to settle on a specific weight. To speed up this process it

is recommended to set the indicator to a lower sensitivity. This can be achieved by programming

the indicator to read in .5 pounds or .25 kilograms. If set to read in 1.0 or .5 kg. increments it will

take less time for the indicator to settle-down on a specific weight. Please refer to the manual of

the specific indicator for proper operation instructions.

Eagle-

Grip™ Series Attachment Maintenance Checklist

Maintenance

Intervals

1

Mo

6

Mo

12

Mo

3

Yrs

Structural

Steel:

1.1 Check for cracked welds on frame

X

1.2

Flip attachment forward to inspect the ends of both fork pockets

for cracked welds

X

1.3

Lubricate the top and bottom rails of the fork mount frame to

permit the masts to slide left and right

X

1.4

Check masts to see if the 16” distance between the upper and

lower supports that slide on the fork mount frame have become

separated enough to the of point becoming unattached when

lifting a drum

X

1.5 Check the safety chain and cam lock for wear and missing parts

X

1.6

Check to verify that specification data plates are affixed to the

attachment

X

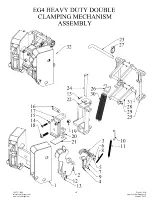

Clamping

Heads:

2.1

Inspect heads for loose or missing pins, cotter pins, springs, pins,

and replace as necessary

X

2.2 Lubricate clamping mechanisms

X

Belts:

3.1 Check belts for wear and adjust for proper tension

X

Pins, Springs,

Inner

housings,

Links:

4.1 Replace all springs

X

4.2 Replace all pins, inner housings, and links

X

Optional

Quick-Claw

5.1 Check to verify springs are intact and functioning properly

X

5.2 Lubricate cam to prevent rust

X

**The maintenance intervals refer to normal service conditions. In case of aggravated conditions, the intervals must be reduced/increased as required.

66