To order parts and supplies: 800.343.9353 >> eastwood.com

29

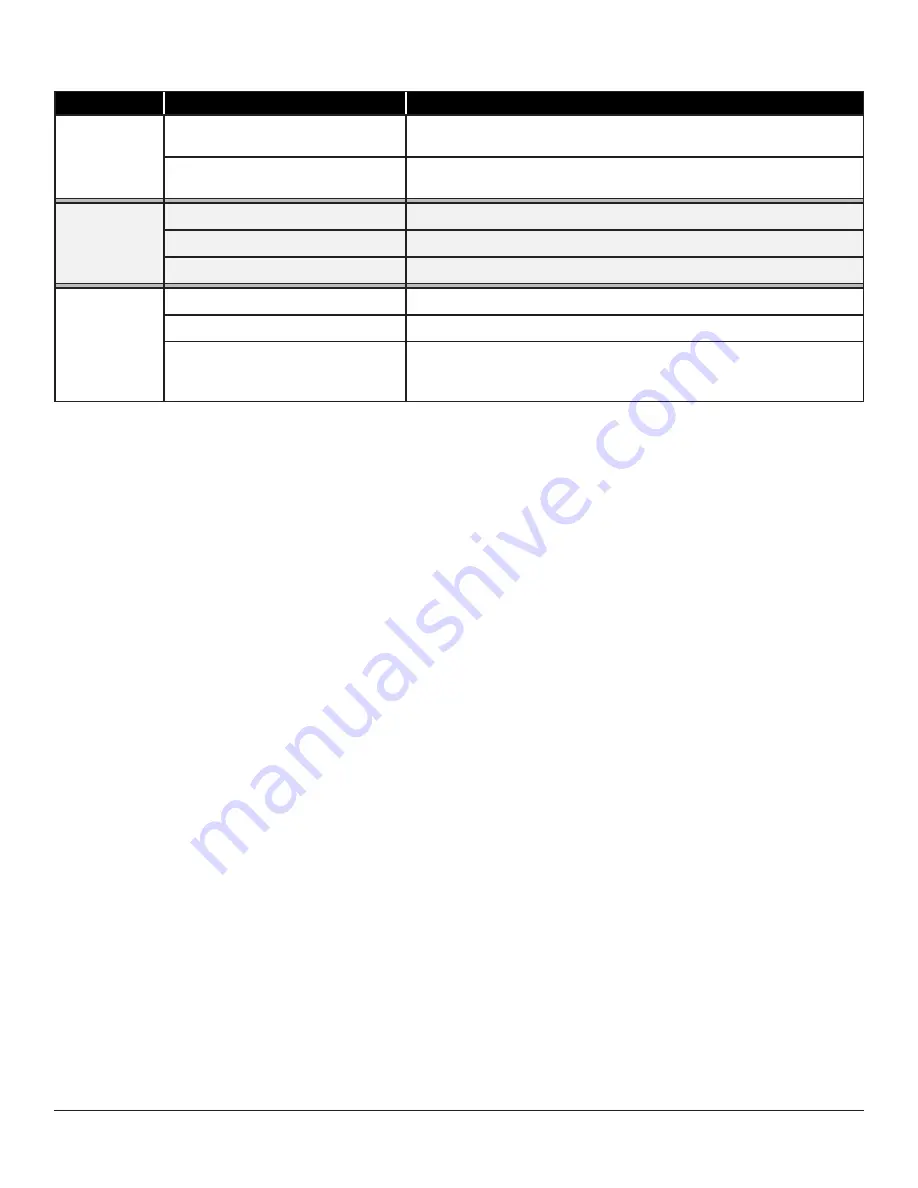

TIG WELDING TROUBLESHOOTING

PROBLEM

CAUSE

CORRECTION

Crater in the

End of the Weld

Bead

Insufficient Shielding

Keep the Torch on the base metal while the post flow shielding gas flows to

protect and cool the metal and Tungsten.

Not Enough Filler Material

Reduce current and add more filler at end of weld. It may also be beneficial to

back step to ensure no crater will form.

Weld Bead is

Cracking

Too Much Heat in Material

Reduce heat and allow more time between passes.

Base Metal is Absorbing Too Much Heat

Preheat base metal (consult welding codes for requirements)

Incorrect Filler Wire

Use appropriate filler wire type and diameter for the joint being welded.

Material is

Warping

Insufficient Clamping

Clamp work piece tightly and weld while clamps are in place.

Insufficient Tack Welds

Add more tack welds until rigidity and stiffness is developed.

Too Much Heat in Material

To reduce heat it is best to spread the welding out around the area. This can be

done by using stitch welding techniques, alternating sides, and/or taking your

time and allowing the pieces to cool between passes.