To order parts and supplies: 800.343.9353 >> eastwood.com

19

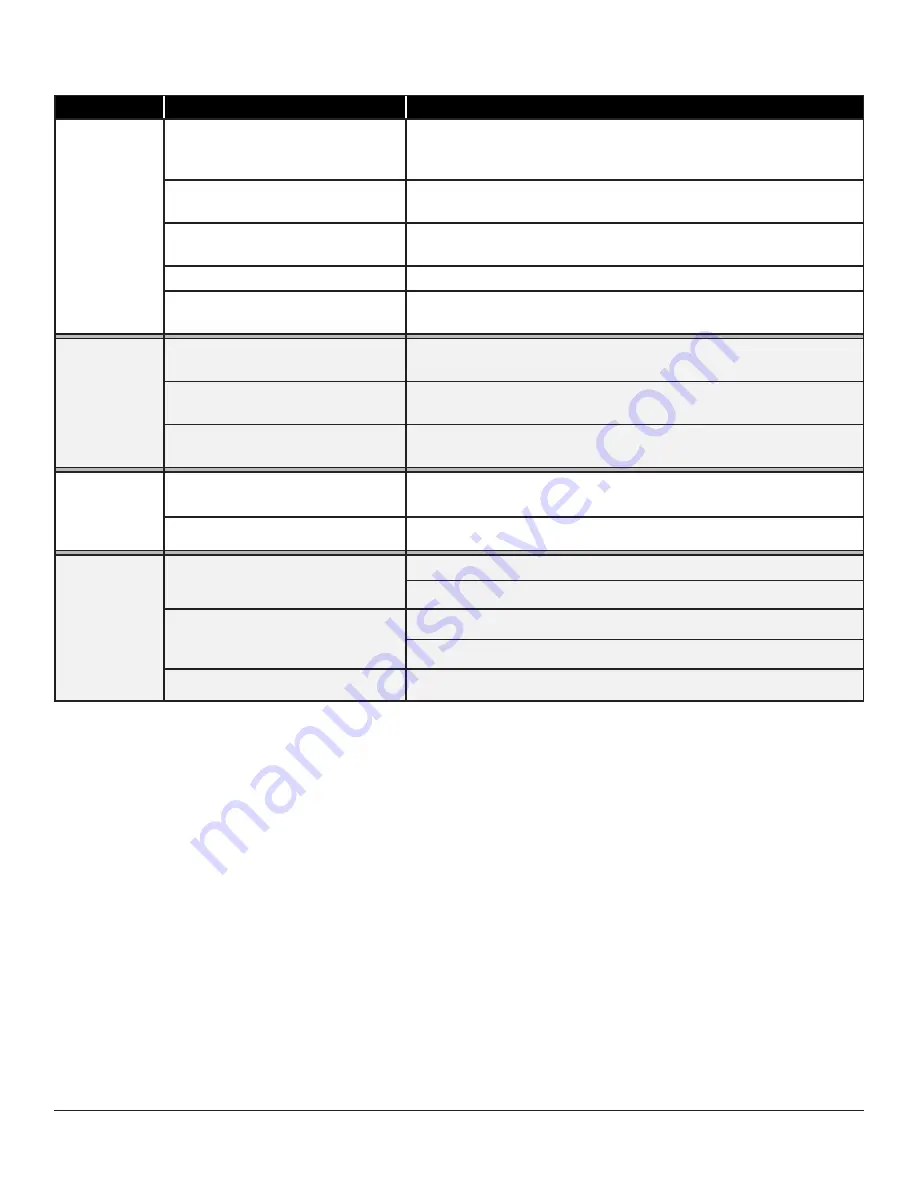

PROBLEM

CAUSE

CORRECTION

Weak Blast

Stream

Compressor Inadequate Causing

Insufficient Volume of Air (CFM)

to Operate Tool

Verify sufficient air supply to tool. Minimum requirement = 12 CFM @ 90 PSI.

Air Supply Line from Compressor

Too Small

Use air supply line of 3/8” or greater.

Air Supply Line from Compressor

Too Long

Limit air supply line to 25’ or less.

Pinched or Damaged Media Suction Line

Replace suction hose. Automotive fuel or heater hose works well.

Moisture or Other Contamination in

Air Supply

Check for and eliminate source of moisture in air line and blast gun.

Media Surging

Moisture in Media and or/Air Supply

Install a moisture separator capable of removing all moisture and impurities

from the air supply.

Debris or Blasting Residue in Gun Nozzle

Clean out gun nozzle then drain and sift blast media to remove debris

before re-use.

Excessive Media in Hopper

For best results, operate blaster with the Pick-up Tube inlet buried several

inches in media. 50 lbs. of media is generally sufficient.

Media Stream

Suddenly

Stops

Dirt or Debris in Media Suction Line

to Gun

To dislodge blockage, with lid closed, place a blast gloved finger over the

nozzle outlet and momentarily depress Foot Pedal.

Contaminated Media

Drain and sift blast media to remove debris before re-use.

View in

Cabinet

Becomes

Obstructed

Dust is Clogging Filter

Operate Filter Plunger to shake dust form Filter.

Clean Filter per procedure in Maintenance Section.

Filter Housing is Full of Dust

Empty Filter Housing per procedure in Maintenance Section.

Clean Filter per procedure in Maintenance Section.

Plastic Peel-Off Shield is Worn

Clean inside of window and replace Peel-off shield.

TROUBLESHOOTING