Form C-1519

5

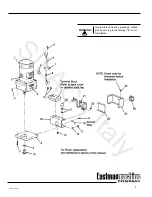

TO ADJUST EMERY WHEELS

As the Emery Wheels wear away and become farther

apart, they must be adjusted. Emery Wheels must be

adjusted from

both sides to assure proper centering of the wheels over

the knife.

To adjust, loosen slotted head screws “A”. With fingers, turn

adjusting bushings “B” until Emery Wheels are as close

together as possible without touching and are centered

over the knife. Both wheels should grind at the same time

when pressed lightly against the knife and there should be

no more than 1/32 inch clearance between the two Emery

Wheels. Tighten slotted head screws “A”.

TO REPLACE EMERY WHEELS

With front of machine facing serviceman, guard rod in

down safe position, remove right hand grinding wheel and

arm by loosening setscrew “D” and sliding arm off shaft.

Remove slotted head screw “C” and replace grinding wheel

with spindle in right hand arm. Do not remove left hand

arm from machine. Remove slotted head screw “C” from

left hand arm and replace grinding wheel with spindle.

Re-assemble right hand arm to shaft and adjust wheels to

knife as described above.

MOTOR BRUSH REPLACEMENT

With electrical cord disconnected, unsnap Brush Cover

(53C11-165) from motor and remove cover. Remove Brush

Spring (34C1-62) from brush holder by pushing in, then

release. Gently pull brush wire to remove Brush (708C1-

18) and check for wear. If brush is less than

3/8" in length, brush must be replaced. Disconnect terminal

from tab on motor.

Before inserting new brushes, use air hose or bellows with

proper eye protection and blow dust out of motor. When

inserting new brushes, brush wire must face slot in brush

holder. Connect brush terminal to tab on motor. Place

brush spring in guide with spring facing brush. With small

screwdriver slide clip down and lock clip in place, as shown.

Snap brush cover in place.

SILAC

- Italy