4

Form C-1519

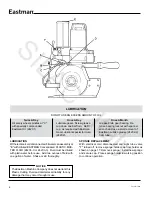

LUBRICATION

DO NOT USE AN EXCESS AMOUNT OF OIL

Twice A Day

Oil emery wheel spindles at "C"

with specially compounded

Eastman Oil (242C1).

Once A Month

Grease Knife gear bearing. Re-

move bearing locknut with spanner

wrench and use a small amount of

Eastman Lubriko grease (242C2-2)

from tube.

Once A Day

Lubricate gears. Screw grease

cup down one-half turn. Refill

cup, as required with Eastman

Gear Lubricant special formula

(242C2).

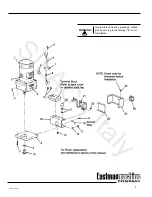

LUBRICATION

With electrical cord disconnected, fill water can assembly at

"E" with diluted EASTMAN Concentrated PLASTIC MAS-

TER FLUID (242C3-0 or 242C3-3). Fluid must be diluted

with plain water before use. Add two ounces of fluid with

one gallon of water. Shake or stir thoroughly.

NOTICE

The Eastman Machine Company does not warrant this

Plastic Cutting Fluid and disclaims all liability for any

damage that may occur through its use.

SPONGE REPLACEMENT

With electrical cord disconnected and sight tube valve

"F" turned off, remove sponge holder cap from holder as

shown on page 17. Remove sponge. Install new sponge

and secure cap. Place sponge holder in working position

to continue operation.

SILAC

- Italy