8

Field Joint Assembly Instructions

Parts included in Field Joint Kit:

Identify all parts before proceeding

with installation.

(16) 3/8-16 x 1-1/2 long screws

(16) 3/8-16 Elastic Stop Nuts

(32) Flat Washers

(1) Length Sealant (Sika) Tape

(1) Hole Punch

(1) Vent Pipe Extension

1) Carefully clean and dry both

accessway flanges with solvent.

IMPORTANT: Sealing surfaces

must be dry to ensure the

sealant adheres correctly.

2)

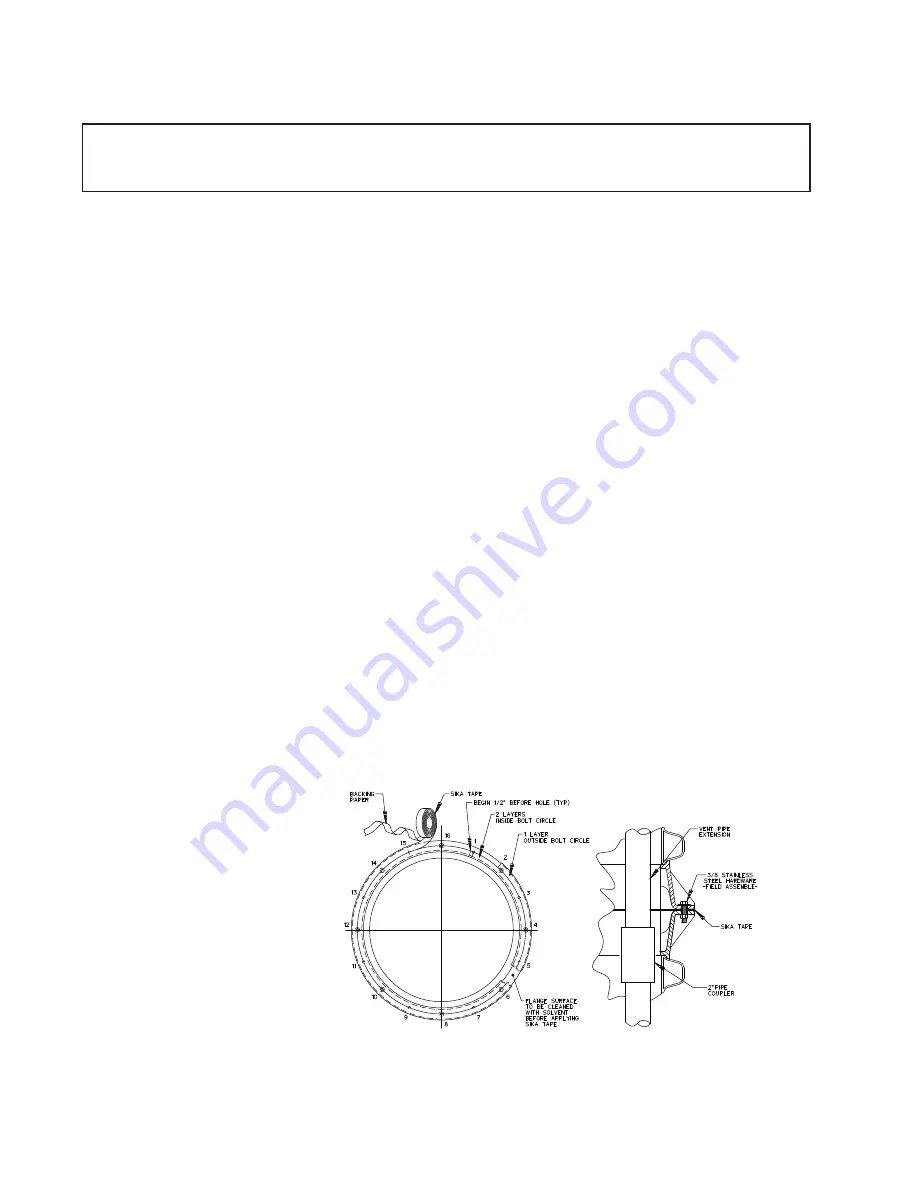

Starting at one hole of tank

flange, apply two layers of Sika

Tape around the inside half of the

flange. Align the outside edge of

the tape with the bolt circle. Move

to the adjacent hole and apply

one layer of Sika Tape around

the outside of the flange. Align

inside of tape with the bolt circle.

Remove the backing paper as you

lay the adhesive on the flange.

Do not stretch Sika tape during

application; it may result in a

leak.

The tape should overlap at

the end by approximately 1/2 inch,

as shown in Fig. 5a. If a section

of Sika Tape is misapplied, the

bad section may be cut out and

replaced. Cut away the poorly laid

portion cleanly with a knife and be

sure to over lap the tape at each

end about 1/2 inch.

3) Using the tool provided,

punch a hole through the tape at

each of the 16 existing bolt holes

in the flange.

Be careful to keep

the exposed sealant clean and

dry.

4) Insert three of the sixteen 3/8-

16 x 1-1/2” long bolts, with a flat

washer, into the flange attached to

the upper part of the accessway.

These will act as guides while

aligning the bolt pattern of the two

flanges.

5) Support the upper accessway

section a few inches over the

tank, making sure to align the vent

port in the lid with the vent pipe

in the tank. Once aligned, lower

the upper section onto the mating

flange using the three bolts to

guide it to the proper position. See

Fig. 5b.

6) Insert the remaining 13 bolts

with flat washers into the flanges.

Place a flat washer and elastic

stop nut on the end of each bolt,

turning the nut on just enough to

hold the washer in place.

7) Tighten the bolts until the

sealant begins to squeeze out

from between the flanges. To

ensure a consistent, sturdy seal,

tighten them in the following

sequence: 1, 9; 5, 13; 3, 11; 7, 15;

2, 10; 4, 12; 6, 14; 8, 16. Always

be sure to tighten one bolt and

then the bolt at the position 180°

from it; see Fig. 1 for position

numbers.

8) Using the same sequence as

in Step 7, tighten each bolt to 60

in-lbs. Visually inspect the joint,

each bolt and each nut should

have a flat washer between it and

the flange, and a uniform amount

of sealant should be protruding

from the seam along the entire

perimeter.

In the event that there are

any voids in the sealant, the

joint may leak. Take corrective

actions if necessary and be

sure that the joint is leak free

before continuing.

9)

In order to properly vent

the station, apply PVC primer/

cement (not provided) and

assemble the included sections

of vent pipe by using the

provided 2” PVC couplings.

After the pipe sections have

been assembled, ensure that

the bottom end of the pipe

is secured in the lower vent

grommet, then slide the top

end of the pipe through the

receptacle on the bottom of the

lid.

IT IS EXTREMELY IMPORTANT THAT THE JOINT IS SEALED PROPERLY BEFORE

BACKFILLING. EXCAVATING A UNIT FOR REPAIR IS VERY EXPENSIVE AND CAN BE EASILY

AVOIDED BY USING PROPER CAUTION DURING THE FOLLOWING PROCEDURE.

Figure 5a

Figure 5b