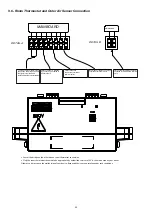

2. Exhaust Gas Tap

7. Flange Gaskets

3. Air Inlet Tap

8. Flue Exhaust Terminal

4. Sealing Gasket Ø60 or Ø80

9. Inner Wall Connection Flange

5. Sealing Gasket Ø 100 or Ø125

10. Outer Wall Connection Flange (EPDM)

Table 2

7. FLUES

7.1- Flue Sizes

Flue gas connections between the boiler and the flue terminal must be made using original components specially

designed for the condensing boiler to ensure that the device operates efficiently and correctly.

Flue gas pipes and fittings of non-condensing boilers can not be used for exhausting gases from condensing

boilers. In the horizontal concentric flues, the exhaust gas pipe (the inner pipe) facing outwards should be inclined

upward and the fresh air pipe (outer pipe) should be inclined downward. When the original flue set is installed

parallel to the ground, the exhaust gas pipe is automatically inclined upwards.

Equivalent length for each 90

0

elbow: 1 m

Equivalent length for each 45

0

elbow: 0.5 m

7.2- Flue Types

Figure 7

1. 90° C Elbow

6. Flange Screws

13

Summary of Contents for Proteus Premix PPR 14 HCH

Page 9: ...5 4 Technical Specifications 9 ...

Page 10: ...10 ...

Page 28: ...28 ...

Page 29: ...Table 4 29 ...

Page 32: ...16 INSTALLATION TEMPLATE 16 1 HM Model 32 ...

Page 33: ...E E L C 160 mm 00 160 mm cJiD E E o o L C E 16 2 HCH Model 33 ...

Page 34: ...E E L C 160 mm 00 C 160 mm E E o o L C E 16 2 HST Model 34 ...

Page 36: ...36 ...

Page 37: ...37 ...

Page 38: ...38 ...

Page 39: ...39 ...

Page 41: ...41 ...