DYNISCO PG500 Series

3

33

3

3

3

33

3

3

2.

INSTALLATION

After lubricating the probe thread as described, install the probe in the

mounting hole with the hex nut provided at the top of the probe.

• DO NOT ATTEMPT TO SCREW UNIT IN BY TWISTING GAUGE

ENCLOSURE.

A mounting torque of 100 inch lbs. should provide an adequate seal,

although the stem will withstand up to 500 inch lbs.

*A mounting hole which has become damaged, distorted or partially

filled with plastic can render a gauge inoperative as easily as one which

is not properly machined.

*A cleaning tool kit (Dynisco P/N 200100) is available which is

designed to remove excess plastic from the 0.312 diameter hole, the

45° seat, the 0.451 diameter and the threads. A gauge plug is

included in this kit.

2.1

Gauge Enclosure Rotation

Once installation has been completed, the gauge enclosure can be

swiveled 310° to provide optimum visibility. To do this, rotate the

enclosure to the desired position. Do not attempt to force enclosure

rotation beyond the built-in mechanical stops.

2.2

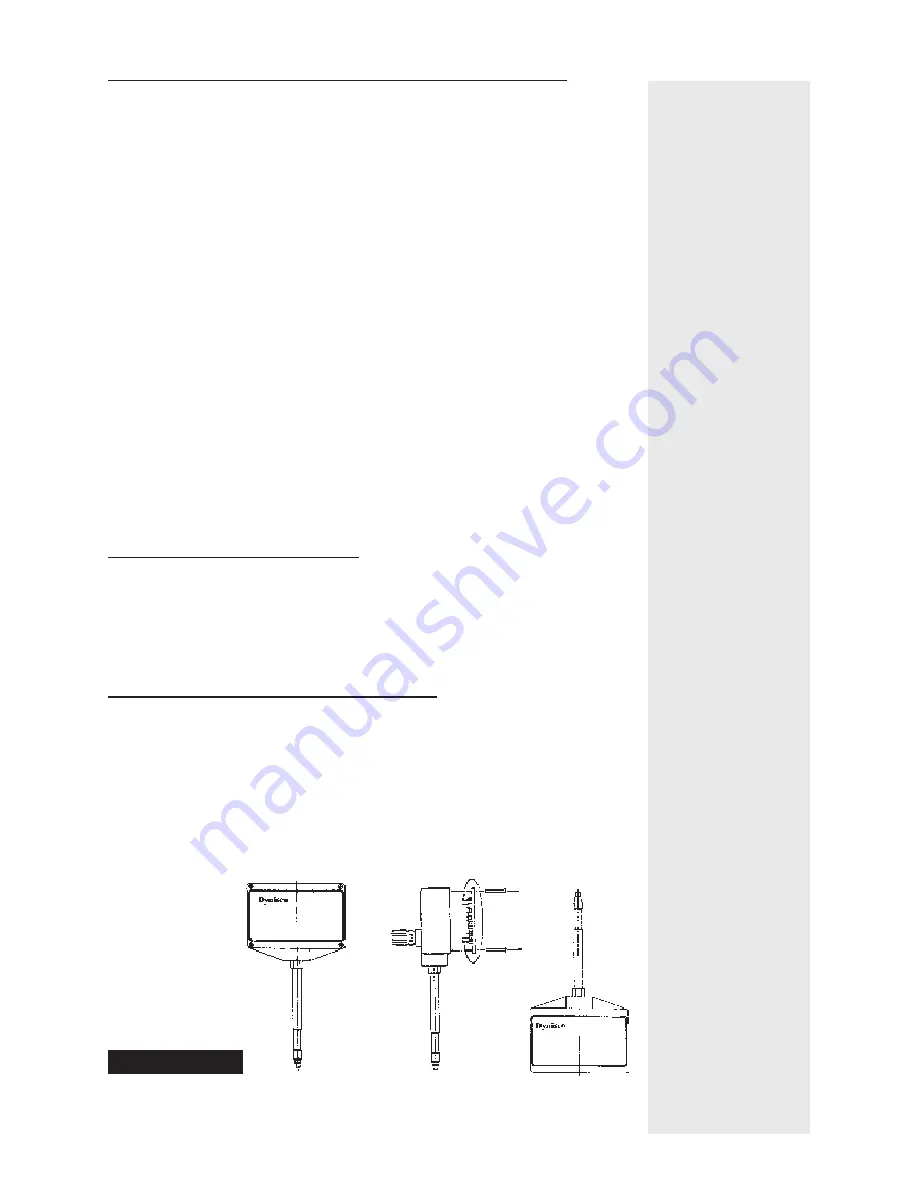

Stem Up - Stem Down Modification

All PG500 Series gauges are shipped from the factory in a stem down

configuration (Figure 5). For those installations which require a stem

up configuration, (mounting on bottom of extruder barrel) merely

remove the four corner screws on the gauge face and gently lift the

face plate off (Figure 5). Reinstall face plate upside down and re-

tighten corner screws.

Fig. 5