M0726(2):LMFI Series 5000 Lab Melt Flow Indexer

38

English 02/2014

If you don't use gloves, you will eventually get burned. If you are using PVC die

(D3364 for unstable materials), be sure to get the material out of the conical top section.

Standard dies have a flat entrance and exit. When the die is out of the barrel it cools down

quickly. The longer it is out, the longer the wait for the temperature to stabilize will be.

Minimizing the time the die stays out of the machine will increase the number of tests you can

run. When the temperature on the front display is within 0.2 C of the set point, you can begin the

next test. Loading material will cause a small temperature change even if the temperature set

point is locked in. The melt time (360 seconds) will allow ample time to get the temperature to

the set point and stabilize before the first data point is collected.

Always leave the machine clean. If it is going to sit at room temperature for an extended period

of time, you may wish to coat the barrel with a light machine oil to prevent rusting. The oil will

need to be cleaned with cleaning patches from the machine before accurate data can be

obtained.

Warning

:

Do not heat the barrel back to elevated temperatures before cleaning the

machine oil from the barrel. Noxious fumes and/or fire hazard exists if not cleaned.

TROUBLESHOOTING

Actions

Getting wrong or non-repeatable test values:

Was the instrument clean?

Check density value

Check tip diameter (> 0.3727)

Check Die (clean, diameter length OK?)

Check Machine is Level

Check Temperature

Check weights used +/- 0.5%

Check balance used to weigh extrudate

Piston Rod Bent?

Check die can get to bottom of barrel?

Generic Run Check List

Prior to loading Sample:

Is material properly prepared (dried, mixed, check for contaminates)?

Machine on for 20 minutes to temperature stabilize?

Correct Die in machine?

Correct program being run?

Hand tools in position for run (packing funnel and tool, cleaning drill bit etc.)?

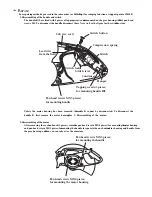

Encoder Arm in place?