EN

2

3

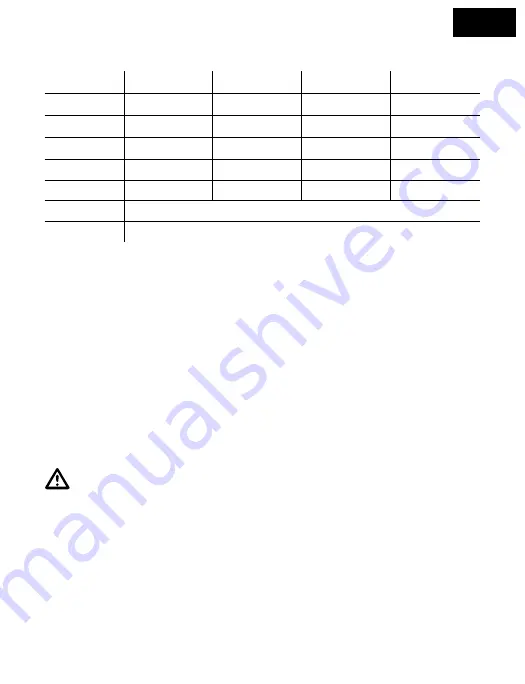

Specifications

DYN3754

DYN3755

DYN3756

DYN3757

Diameter

36mm (1.42 in)

36mm (1.42 in)

36mm (1.42 in)

36mm (1.42 in)

Case Length

50mm (1.97 in)

50mm (1.97 in)

50mm (1.97 in)

50mm (1.97 in)

Weight

200 g (7.05 oz)

200 g (7.05 oz)

200 g (7.05 oz)

200 g (7.05 oz)

Shaft Diameter

3.17mm (1/8 in)

3.17mm (1/8 in)

3.17mm (1/8 in)

3.17mm (1/8 in)

Kv Rating

3800Kv

4800Kv

5800Kv

6800Kv

Cells

6–10 Ni-Cd/Ni-MH or 2S–3S Li-Po

Brushless ESC

Fuze 1/10 Brushless ESC (DYN3741, DYN3780) or equivalent

Gearing

Improper gearing will cause excessive heat

buildup in the motor and speed control. Use

your vehicle’s kit manual in order to find the

manufacturer’s recommended pinion size. It is

best to monitor the motor’s operating temperature

when you are operating on new and different

tracks or racing surfaces, changing to a new

motor or making gearing changes. Your motor’s

operating temperature should never exceed 160°

F (71° C). The best place to monitor the motor’s

temperature is at the center of the end bell. If the

motor temperature is higher than 160° F (71°

C) after a 5 minute run, the gearing should be

lowered (change to a smaller pinion gear).

CAUTION:

Once the battery is connected

to the motor, stay clear of the rotating shaft and

pinion gear. Failure to do so could result in

personal injury.

Installation of the Motor

Always make sure the motor mounting screws

are long enough to properly seat into the motor.

However, ensure the screws do not enter into the

motor too far, which could damage the motor.

The maximum depth that the motor mounting

screws can enter into the motor is approximately

1/8 in (3mm). We suggest using the motor

mounting hardware included with your vehicle.

The use of screws that are too long will damage

the motor and void any warranty.

When installing the motor into your vehicle, it

is very important that the gear mesh is correct

and smooth with no binding. The vehicle’s

motor mounts usually feature adjustable slotted

mounting holes so that you can adjust the gear

mesh properly.

Proper gear mesh (how gear teeth meet) is

important to the performance of the vehicle. When

the gear mesh is too loose, the spur gear could

be damaged by the pinion gear of the motor. If the

mesh is too tight, speed could be limited and the

motor and ESC will overheat. Insert a small piece

of paper in between the pinion and spur gears as

you are installing them. Push the gears together

while tightening the screws that mount the motor.

When the mesh is at the correct distance, remove

the small piece of paper by rotating the spur gear

until the paper comes out. Check the mesh at

multiple points around the larger spur gear before

finalizing the motor mounting position.