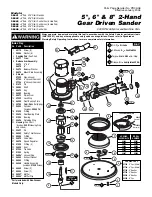

Disassembly/Assembly Instructions

Important: The manufactures warranty is void if the tool is disassembled before the warranty expires. Use these instructions in conjunction with the Part Number

96283 Tool Repair Kit. This kit includes special tooling for the proper disassembly/assembly of the Two-Hand Gear Driven Sander. This Tooling will be referred to in

these instructions. An air motor Tune-Up Kit, Part Number 98221 is also available. It contains the high and medium wear components that most

commonly need replacement.

Motor Disassembly:

1.

Disconnect the sander from the air supply.

2.

Use the

57092

Repair Collar to hold the sander in a vise. Position the sander so that the sanding pad is facing up.

Note:

Do not over tighten the collar and sander in the

vise. Only hold the sander snugly, so that the motor lock ring can be removed easily.

3.

Use a 9/64" hex key wrench to remove the screws and sanding pad from the sander.

4.

Use a 5/32" hex key wrench to remove the balance arm assembly by turning the hex key counterclockwise.

5.

Remove the

56474

Balance Washer and

56470

Mount Plate Assembly.

6.

Use the

56599

Lock Ring Tool to remove the

57332

Lock Ring by turning it counterclockwise.

7.

Pull the air motor assembly out of the housing.

8.

Use retaining ring pliers to remove the

95626

Retaining Ring.

9.

Remove the

01020

O-Ring from the

56595

Cylinder and fasten a 2" bearing separator around the part of the cylinder that is closest to the

54629

Rear Bearing Plate.

10.

Place the air motor with the bearing separator attached, onto the table of the

96232

, #2 Arbor Press so that the balance end of the

56589

Shaft is pointing down.

11.

Use a 5/16" dia. flat end drive punch as a press tool to push the shaft out of the

01206

Bearing. Use the

96213

Bearing Removal Tool (bearing removal tool not included

in the

96283

Repair Kit) to push the

01206

Bearing out of the

54629

Rear Bearing Plate.

12.

Remove the cylinder, rotor, vanes, and key.

13.

Use the arbor press to push

56052

bearing and the

56589

Shaft out of the

56594

Front Bearing Plate.

14.

Use a 2" bearing separator and arbor press to remove the

56052

Bearing from the

56589

Shaft.

15.

Use a 2" bearing separator and arbor press to remove the

56473

Pinion Gear from the

56594

Front Bearing Plate.

Motor Disassembly Complete.

Motor Assembly:

Important: Clean and inspect all motor parts for wear or defect.

1.

Orient the open side of the

56052

Bearing toward the balance end of the

56589

Shaft.

2.

Use the small end of the

50791

Bearing Press Tool and the

96232

, #2 Arbor Press to push the

56052

Bearing onto the shaft until the I.D. of the bearing sits against the

shaft step. (Drawing 1)

3.

Install the

57332

Lock Ring onto the

56594

Front Bearing Plate so that the threaded portion of the lock ring sits against the bearing plate.

4.

Use the arbor press to press the

56473

Pinion Gear onto the front bearing plate. Note: Press the pinion gear onto the bearing plate so that the edge of the bearing plate

stands slightly above the pinion gear.

5.

Use the large end of the

57091

Bearing press Tool and the arbor press to install the front bearing plate onto the

56052

Bearing. (Drawing 2)

6.

Install the

54673

Key so that the 90° side of the key fits into the keyway of the shaft and the tapered side of the key fits into the rotor. Install the

54705

Rotor/Blade Set (5)

onto the shaft

7.

Apply the

95842

Dynabrade Air Lube (10W/NR or equivalent) to the blades.

8.

Install the

56595

Cylinder over the rotor so that the short line-up pin fits into the front bearing plate.

9.

Place the

54629

Rear Bearing Plate over the shaft so that the long line-up pin fits through the hole in the rear bearing plate.(Drawing 3) Use the small end of the

57091

Bearing Press Tool to install the

01206

Bearing onto the shaft and into the

54629

Rear Bearing Plate. Use the press tool and the arbor press to install these so that there

is a snug fit between the bearing plates and the cylinder.

Note:

Carefully press the

01206

Bearing onto the motor shaft until it touches against the bearing seat on the

inside of the bearing plate. (Drawing 4)

10.

Use retaining ring pliers to install the

95626

Retaining Ring so that the concave side of the ring is toward the motor assembly.

Note:

Be sure that the retaining ring is

completely pressed down into the groove on the shaft.

11.

Use the

57092

Repair Collar to hold the housing in a vise so that the opening for the housing is facing up.

12.

Apply a small amount of petroleum lubricant to the

01020

O-Ring and install the o-ring into the air inlet hole in the cylinder.

13.

Install the motor assembly into the housing making sure to align the line-up pin with the line-up hole that is on the inside of the housing.

14.

Use the

56599

Lock Ring Tool to secure the motor in the housing. (Torque to 34 N·m/300 in. lbs.)

15.

Install the appropriate shroud onto the housing.

16.

Apply a small mount of the

95542

Grease to the mount plate gear and then install the

56470

Mount Plate Assembly and the

56474

Balance Washer onto the

56589

Shaft.

Apply a small amount of the Loctite #243 (or equivalent) to the I.D. threads of the

56589

Shaft. Hold the balance arm assembly stationary with an adjustable wrench and

use a 5/32" hex key to tighten the

96477

Screw by turning it clockwise. (Torque to 9N·m/80 in. lbs.)

17.

Use the

95541

Grease Gun to apply 2 full plunges of the

95542

Grease through the grease fitting that is located in the

56470

Mount Plate Assembly. Two full plunges of

grease should be applied after every 300-hour interval of use.

18.

Use a 9/64" hex key wrench to install a weight-mated sanding pad.

Motor Assembly Complete.

Handle and Valve Disassembly:

1.

Place the

57092

Repair Collar around the housing so that the handle is pointing up.

2.

Use a Phillips screwdriver to remove the four screws that fasten the handle to the housing. Carefully pull the handle from the housing. This provides access to the tip

valve components, also the handle o-ring, gasket and vacuum plug.

3.

Use a 1/8" dia. flat end drive punch to remove the

95627

Pin and the

56582

Safety Throttle Lever.

4.

Pull the

56578

Speed Regulator and valve stem out of the housing.

Handle and Valve Disassembly Complete.

Handle and Valve Assembly:

1.

Place the

57092

Repair Collar around the housing so that the handle mounting area is facing up.

2.

Install the

01025

O-Rings (3) onto the

56578

Speed Regulator, apply a small amount of petroleum lubricant to the o-rings and insert the regulator assembly into the

housing.

Note:

Be careful that the o-rings do not get caught and pulled out of the o-ring grooves.

(continued text and diagrams on next page)