�

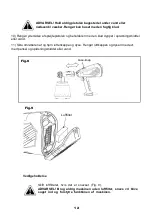

Fig. 7.

Interruption of Work till 4 Hours

n

Turn the machine off.

n

When processing 2-component varnishes, clean the device immediately.

Taking Out of Operation and Cleaning

Proper cleaning is the prerequisite for problem-free operation of the paint application device.

No warranty claims are accepted in case of improper or no cleaning.

1) Unplug the power plug. Vent the container in case of longer breaks and after the work has

been terminated. This can be done by briefly turning open and then closing the container or by

pulling the trigger guard and letting the paint into the original paint container.

2) Divide the spray gun. Press the unlock button (Fig. 8) downwards.

3) Unscrew the container. Empty any remaining coating material back into the material tin.

4) Preclean the container and suction tube with a brush.

5) Pour solvent or water into the container. Screw the container back on. Use only solvents

with a flashpoint over 21°C .

6) Assemble the gun again.

7) Insert the power plug, turn on the machine and spray the solvent or water into a container

or a cloth.

8) Repeat the above procedure until the solvent or water emerging from the nozzle is clear.

9) Turn of the machine and remove the plug.

CAUTION!

Never clean seals, diaphragm and nozzle or air holes of the spray gun with metal objects.

The ventilation hose and diaphragm are only solvent-resistant to a limited extent. Do not

immerse in solvent, only wipe.

CAUTION!

Never clean seals, diaphragm and nozzle or air holes of the spray gun with metal objects.

The ventilation hose and diaphragm are only solvent-resistant to a limited extent. Do not

immerse in solvent, only wipe.

A

B

n

When coating material builds up on the nozzle (A) and air cap (B) (Fig. 7), clean both

parts with a solvent or water.

23