HDI-03-W

Mar ‘15

- 14 -

Compressor Unit Accessories (cont’d)

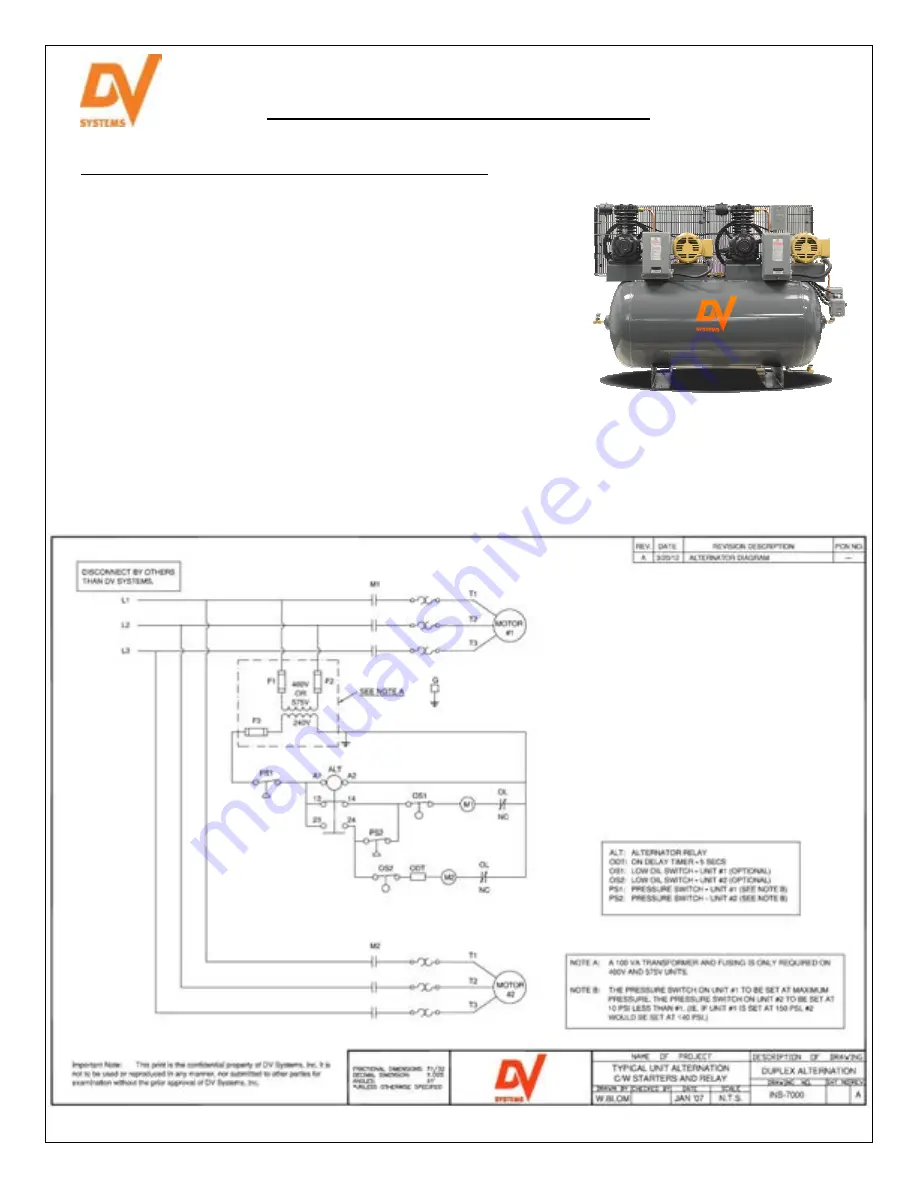

Alternator Relays on Duplex Compressor Units.

An Alternator Relay is used with a Duplex Compressor Unit, namely a

Unit with two Pumps and two Motors on one large Tank. Coupled with

two Magnetic Starters, the Alternator Relay allows the Pumps to

alternate back and forth. This is necessary to spread the compressed air

load over the two Pumps.

Designating the Pump and Motor assemblies on the Tank as being Unit

#1 and Unit #2 allows the alternating to take place. The ‘Lead Pressure

Switch’ (or ‘PS1’) regulates the starting of the Units, and is therefore set

at the maximum pressure setting. (In smaller Compressors, this is

generally the Switch with the Unloader.) The ‘Lag Pressure Switch’ (or

‘PS2’) is set at 5 to 10 psi less than the Lead Switch, and will bring the

second Unit on only if the pressure in the Tank goes below that of the

‘cut-in’ pressure of ‘PS2’. (For example, this will occur when the Unit is

started at 0 psi in the Tank.)

Duplex Units having voltages of 460 or 575 have a Step-down Transformer and Primary and Secondary Fusing.

Shown below is a typical schematic for a Duplex Unit c/w (2) Magnetic Starters and Alternator Relay.