2.8

Wheel feed

Rule:

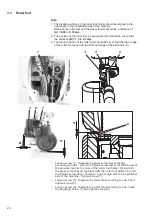

1. The wheel feed elevation

(A)

over the throat plate insert should be

adapted to the material thickness and hardness:

Soft or thick materials –

0.6 mm

Thin materials –

0.2 mm

2. The wheel feed knurling should be adapted to the sewn material

character:

Soft material – the wheel feed with a crosswise knurling to suppress

the prints on the material surface.

Thick material – the wheel feed with larger straight teeth.

15

EN

A

8

7

6

1

9

2

5

4

Summary of Contents for 884-xxx-M series

Page 1: ...884 Service Instructions ...

Page 34: ...32 4 3 5 ...