Needle bar and hook

42

Service Instructions 52Xi, 52Xi-75 - 00.0 - 11/2021

7.3

Hook lifting

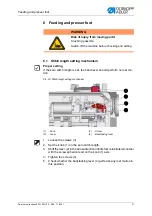

Proper setting

In the direction of the hook axis there should be the space (A) = 0,8 mm

between the bobbin case lifter and the hook. The maximum hook lifting

should be (B) = 0,4 to 0,8 mm according to the thread thickness. The tim-

ing of the lifting eccentric should enable a smooth passage of the thread

between the bobbin case and the bobbin case lifter (C) = 1 mm.

Pic. 31: Hook lifting

1.

Dismount the throat plate (

2.

Tilt the machine (

3.

Loosen the screw (4) and shift the case (2) to obtain the space (A) =

0,8 mm and tighten the screw (4).

4.

Turn the hand wheel until the bobbin case lifter (5) is in the maximum

lifting position (left position). Loosen the screw (3) and turn the bobbin

case lifter so that the space (B) = 0,4 to 0,8 mm is achieved according

to the thread thickness.

(1) - Screw

(2) - Case

(3) - Screw

(4) - Screw

(5) - Bobbin case lifter

②

③

①

A

⑤

④

B

C

Summary of Contents for 52 i Series

Page 1: ...52Xi 52Xi 75 Service Instructions ...

Page 8: ...About these instructions 6 Service Instructions 52Xi 52Xi 75 00 0 11 2021 ...

Page 20: ...Working basis 18 Service Instructions 52Xi 52Xi 75 00 0 11 2021 ...

Page 74: ...Maintenance 72 Service Instructions 52Xi 52Xi 75 00 0 11 2021 ...

Page 76: ...Decommissioning 74 Service Instructions 52Xi 52Xi 75 00 0 11 2021 ...

Page 78: ...Disposal 76 Service Instructions 52Xi 52Xi 75 00 0 11 2021 ...

Page 83: ......