Programming

296

Service Instructions 745-35-10 S/745-35-10 A - 02.0 - 04/2017

Update machine software

Information

The update is performed in 2 steps.

The control panel OP7000 is updated first.

In a second step, a software update is performed for the control

(DAC comfort).

To perform an update of the machine software:

1.

Download the update file from Dürkopp Adler’s website.

The file is named, for example:

9899_DAC001_000_A01.27_2016-02-14.jcbi

2.

Copy the update file to a blank Dürkopp Adler USB key

(part number 9835 301003).

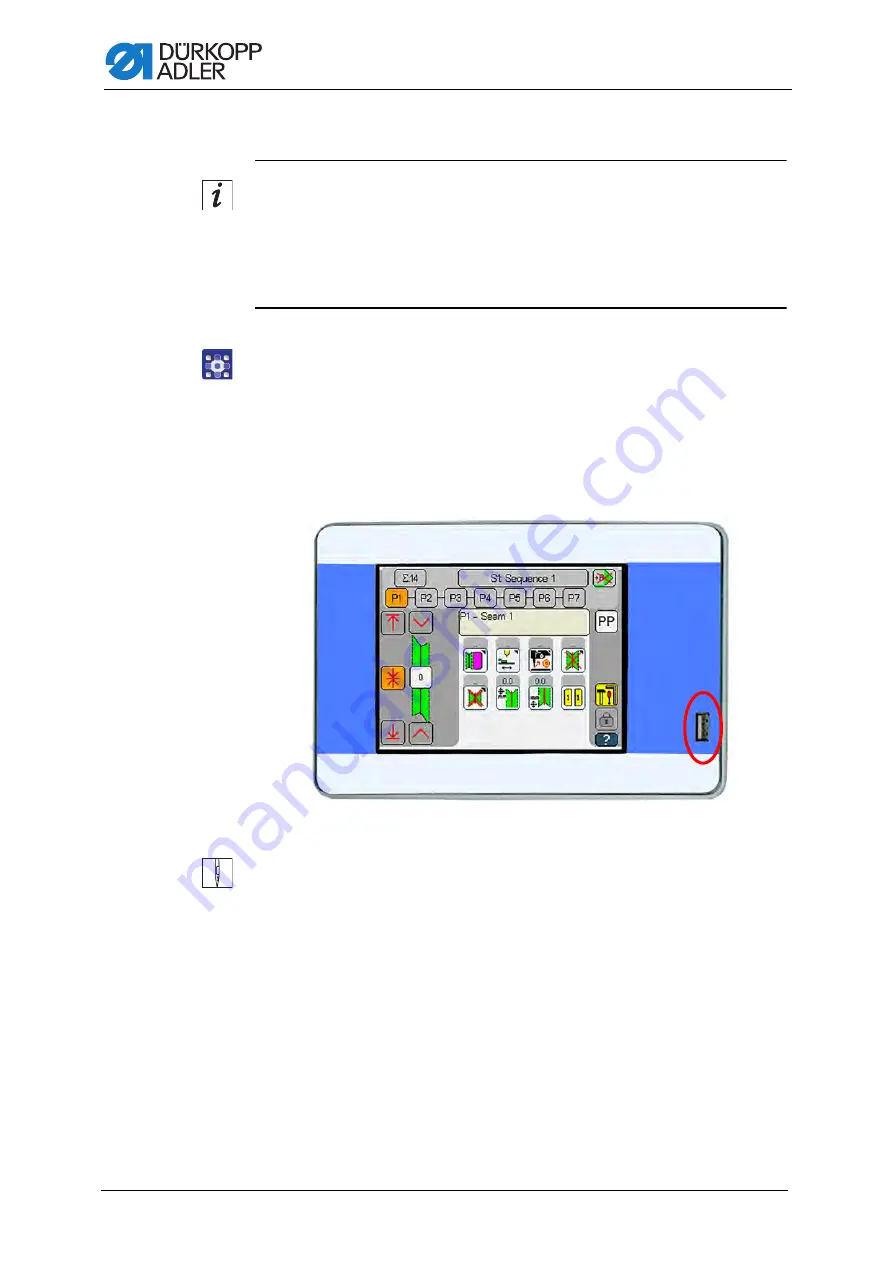

Fig. 257: Update the machine software (1)

3.

Switch off the machine and wait for approx. 15 seconds.

4.

Connect the Dürkopp Adler USB key to the OP7000.

5.

Restart the machine.

The OP7000 boot loader appears:

Summary of Contents for 745-35-10 A

Page 1: ...745 35 10 S 745 35 10 A Service Instructions...

Page 10: ...About these instructions 8 Service Instructions 745 35 10 S 745 35 10 A 02 0 04 2017...

Page 13: ...Safety Service Instructions 745 35 10 S 745 35 10 A 02 0 04 2017 11...

Page 16: ...Safety 14 Service Instructions 745 35 10 S 745 35 10 A 02 0 04 2017...

Page 86: ...Transport carriage 84 Service Instructions 745 35 10 S 745 35 10 A 02 0 04 2017...

Page 98: ...Transport clamps 96 Service Instructions 745 35 10 S 745 35 10 A 02 0 04 2017...

Page 134: ...Aligning the machine head 132 Service Instructions 745 35 10 S 745 35 10 A 02 0 04 2017...

Page 148: ...Folder 146 Service Instructions 745 35 10 S 745 35 10 A 02 0 04 2017...

Page 156: ...Additional equipment 154 Service Instructions 745 35 10 S 745 35 10 A 02 0 04 2017...

Page 312: ...Maintenance 310 Service Instructions 745 35 10 S 745 35 10 A 02 0 04 2017...

Page 314: ...Decommissioning 312 Service Instructions 745 35 10 S 745 35 10 A 02 0 04 2017...

Page 316: ...Disposal 314 Service Instructions 745 35 10 S 745 35 10 A 02 0 04 2017...

Page 328: ...Troubleshooting 326 Service Instructions 745 35 10 S 745 35 10 A 02 0 04 2017...

Page 365: ...Appendix Service Instructions 745 35 10 S 745 35 10 A 02 0 04 2017 363 22 3 Pneumatic diagram...

Page 366: ...Appendix 364 Service Instructions 745 35 10 S 745 35 10 A 02 0 04 2017...

Page 367: ...Appendix Service Instructions 745 35 10 S 745 35 10 A 02 0 04 2017 365...

Page 368: ...Appendix 366 Service Instructions 745 35 10 S 745 35 10 A 02 0 04 2017...

Page 369: ...Appendix Service Instructions 745 35 10 S 745 35 10 A 02 0 04 2017 367...

Page 370: ...Appendix 368 Service Instructions 745 35 10 S 745 35 10 A 02 0 04 2017...

Page 371: ...Appendix Service Instructions 745 35 10 S 745 35 10 A 02 0 04 2017 369...

Page 372: ...Appendix 370 Service Instructions 745 35 10 S 745 35 10 A 02 0 04 2017...

Page 373: ...Appendix Service Instructions 745 35 10 S 745 35 10 A 02 0 04 2017 371...

Page 374: ...Appendix 372 Service Instructions 745 35 10 S 745 35 10 A 02 0 04 2017...

Page 375: ...Appendix Service Instructions 745 35 10 S 745 35 10 A 02 0 04 2017 373...

Page 376: ...Appendix 374 Service Instructions 745 35 10 S 745 35 10 A 02 0 04 2017...

Page 377: ...Appendix Service Instructions 745 35 10 S 745 35 10 A 02 0 04 2017 375...

Page 378: ...Appendix 376 Service Instructions 745 35 10 S 745 35 10 A 02 0 04 2017...

Page 379: ...Appendix Service Instructions 745 35 10 S 745 35 10 A 02 0 04 2017 377...

Page 381: ......