9

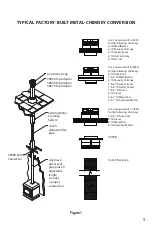

Figure 8

Figure 9

Connector to mount directly on the masonry

and provide clearance to the combustibles.

Refer to Figure 11.

Step 3. Secure the Flashing (705C) to the top

of the masonry chimney using a bead of non-

hardening sealant-adhesive. If the Flashing is

larger than the top of the chimney, then cut

and fold flashing as needed to fit chimney.

See Figure 7.

Step 4. To determine the length of flex

required, measure from 3” above the top

of the Flashing down to the level of the

opening. Add to this measurement the

distance from the center of the chimney to

out through the wall. Cut a piece of 4-inch

flex to this length (the flex should already be

extended to its nominal length).

Step 5. Connect the 4-inch flex liner to the

Top Adapter (985K) using (3) sheet metal

screws. Refer to Figure 2.

Step 6. Feed the 4-inch flex liner through

the Flashing into the chimney. Continue to

feed the liner out through the opening in the

masonry wall.

Step 7. Secure the Top Adapter to the

Flashing. Use (3) sheet metal screws through

the side of the adapter into the flange on the

Flashing, as shown in Figure 8. Twist lock the

Termination Cap (980 or 991) on to the Top

Adapter.

Step 8. Attach the flex to the Retro

Connector. Use (3) sheet metal screws to

attach the flex liner to the Connector. See

Figure 9. Mount the Retro Connector to the

masonry wall using masonry bolts. Re-

drill larger holes on connector as needed.

Be careful to insure that the connector is

centered in the opening and the mounting

holes line up with the masonry wall.

6” diameter

opening in

masonry wall

(3)

Sheet

Metal

Screws

Highwind Termination

Cap

Flashing

Standard

Termination

Cap

Top Adapter

Retro Connector

(3) masonry bolts (not

included)

Summary of Contents for DirectVent Pro

Page 11: ......