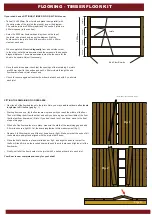

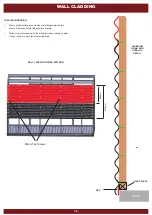

FIXING WALL CLADDING - FRONT

OVERDOOR CLADDING SHEET

Fitting the top cladding sheet on the front wall will be a lot easier with 2

people and 2 ladders...

• Select the 5000mm top front wall sheet (this is not a full width sheet).

Position the sheet making sure it is flush with the top of the front timber

framing and flush with the corner studs at both ends. Fix with 1 x 25mm

Tek screw at each end. Fit the remaining screws once all of the front wall

cladding has been attached.

DOOR SIDE CLADDING - TOP SHEET

• Fit the wall sheets each side of the doorway using the same process

as before. Select a 1300mm cladding sheet and lap it underneath the

overdoor sheet as per normal overlapping standards. Fix with 2 x 25mm

Tek Screws through the overlap.

• Place 2 x more 25mm Tek screws 2 ribs up from the bottom of the sheet

either side so the next sheet down can lap underneath.

The front wall cladding is attached the same way as the other side walls, except that the bottom cladding sheets either side of the roller door will

overlap a lot more than the side and back walls. This will be explained in the step below “BOTTOM SHEET”.

Steel flush with timber frame

Fix with 2x

25mm Tek

Screws

DOOR SIDE CLADDING - MIDDLE SHEET

• Using another 1300mm door side cladding sheet, lap it underneath the sheet above as per normal and place 2 x 25mm Tek screws into the overlap as

normal.

NOTE: do not place any screws in the bottom of this sheet at this stage!

DOOR SIDE CLADDING - BOTTOM SHEET

NOTE: Because of the Overdoor Cladding Sheet at the top of the front wall, the bottom sheet will lap up under the middle sheet by about 5 ribs.

Providing that the sheets have been positioned correctly, the steel profile will match the side walls.

• Take another 1300mm front wall cladding sheet and slide it up under the middle sheet until the bottom of the sheet is approx below the bottom of the shed

framing (the same as the side wall).

• Press the sheets against the framing so that the steel overlaps nice and tight. Align the ends of the steel with the corner stud ad door stud. Now place 2 x

25mm Tek screws into the bottom of the middle sheet. This will hold both overlapped sheets in place.

• Finally screw off all the sheets with 25mm Tek screws as previous (as per previous fixing details).

REPEAT WITH THE CLADDING ON THE OTHER SIDE OF THE DOOR

.

• Finally finish fixing the Overdoor Cladding Sheet - using 25mm Tek screws at each end and into the centre of each of the jack studs above door.

18