ATT2100 TEMPERATURE TRANSMITTER

Operation Manual M2100-REV-G

32

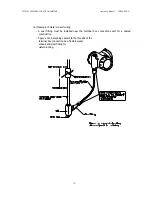

4.9 Loop Configuration

AUTROL Series Transmitters use a two-wire system for power supply, 4~20mA analog signal

transmission and HART digital transmission.

DC Power Supply is required for the transmitter loop. The Transmitter and distributor are connected as

shown below.

(1) Non-Explosionproof / Flameproof Type

Hazardous Location <---------> Nonhazardous Location

Transmitter terminal box Distirbutor Receive

(Power supply unit) Instrument

(2) Explosionproof Type

Hazardous Location <---------> Nonhazardous Location

Transmitter terminal box Distirbutor Receive

(Power supply unit) Instrument