Section 13 -

Complete Electrical Connection

Operates on 110-120V, 60 Hz. current. Shade is shipped with internal wiring complete and control switch

(es)

fully boxed, and supplied with a 6'

(183 cm)

cable lead

(standard)

. Longer lead can be substituted by removing two screws in motor end of roller, removing lead, plugging new lead in, and replacing screws. Wire to connect

shade to switch

(es)

and switch

(es)

to power supply should be furnished by installer. Connections should be made in accordance with attached wiring diagram, and

wiring should comply with national and local electrical codes.

DO NOT wire motors in parallel without written permission from Draper

®

.

All operating switches should be “off” before power is connected.

Section 12 -

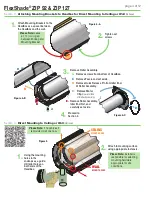

Limit Setting: Standard and Quiet Motors

Caution:

Unit ships without limits. Limits will need to be set

before the unit is operated. Always be prepared to shut off

manually when new adjustment is being tested.

Push Button Limits

1.

Fully depress both limit switch push buttons, then

operate wall switch to make sure system works properly.

2.

Raise shade to desired "UP" stop position.

3.

Set upper limit by depressing proper

(back)

push button.

4.

Lower shade to desired "DOWN" stop position.

5.

Set lower limit by depressing proper

(front)

push button.

Screw-Type Limits

6.

Determine which direction of fabric travel corresponds

with arrows on motor.

Caution:

-

Be sure all switches are in "off"

position before adjusting limit

switches.

-

Shade may be damaged by

running shade fabric up too far

and exposing roller.

-

If using a group control system,

each limit switch must be set

prior to connecting to system.

-

Motor must be installed so

limit switches are pointed up or

accessible.

7.

Operate shade to desired "down" stop position.

Set limit by turning proper socket toward "+" to lower limit, and "-" to raise it.

8.

Operate shade to desired "up" stopping position.

Set limit by turning proper screw toward "-" to raise limit, and "+" to lower it.

Please Note:

Each full rotation of the limit screw equals approximately

5/8

"

(16mm)

of shade travel, which may require rotating the limit screw

several times.

Caution:

DO NOT allow the hem bar to hit the upper roller or fascia.

This will damage the unit.

Caution:

DO NOT allow hem bar to retract into the headbox.

Controls & System Overview

Sonesse

®

RTS 120VAC Motors

B W G

RTS

MOTOR

120V

110-120V Line

Decora RTS

Wireless Keypad

Patio

RF Remote

STOP

Dashed Wiring

by Electrician

NOTE: Test shade operation

If shade direction does not

correspond with the switch

orientation, turn power back

off and switch the red and black

wires from the motor to the switch.

Do not wire motors in parallel without

written permission from Draper.

Controls & System Overview

Sonesse

®

120VAC Motors

W B R G

B

Control

Switch

Single Gang

Box (by others)

120V

MOTOR

110-120V Line

Dashed Wiring

by Electrician

Screws

+

+

Front

Back

Bottom View

Side View

GLASS SIDE

ROOM SIDE

GLASS SIDE

ROOM SIDE

Front

Back

Bottom View

Side View

GLASS SIDE

ROOM SIDE

Front

Back

Bottom View

Side View

Screws

+

+

Front

Back

Bottom View

Side View

GLASS SIDE

ROOM SIDE

Screws

+

+

Front

Back

Bottom View

Side View

GLASS SIDE

ROOM SIDE

PUSH BUTTON LIMITS

Standard right-hand

motor configuration shown

SCREW-TYPE LIMITS

Standard right-hand

motor configuration shown

Sonesse

®

is a registered trademark of Somfy

®

Systems, Inc.

page 9 of 12

FlexShade

®

ZIP 92 & ZIP 127