220V Access MultiView by Draper

page 3 of 4

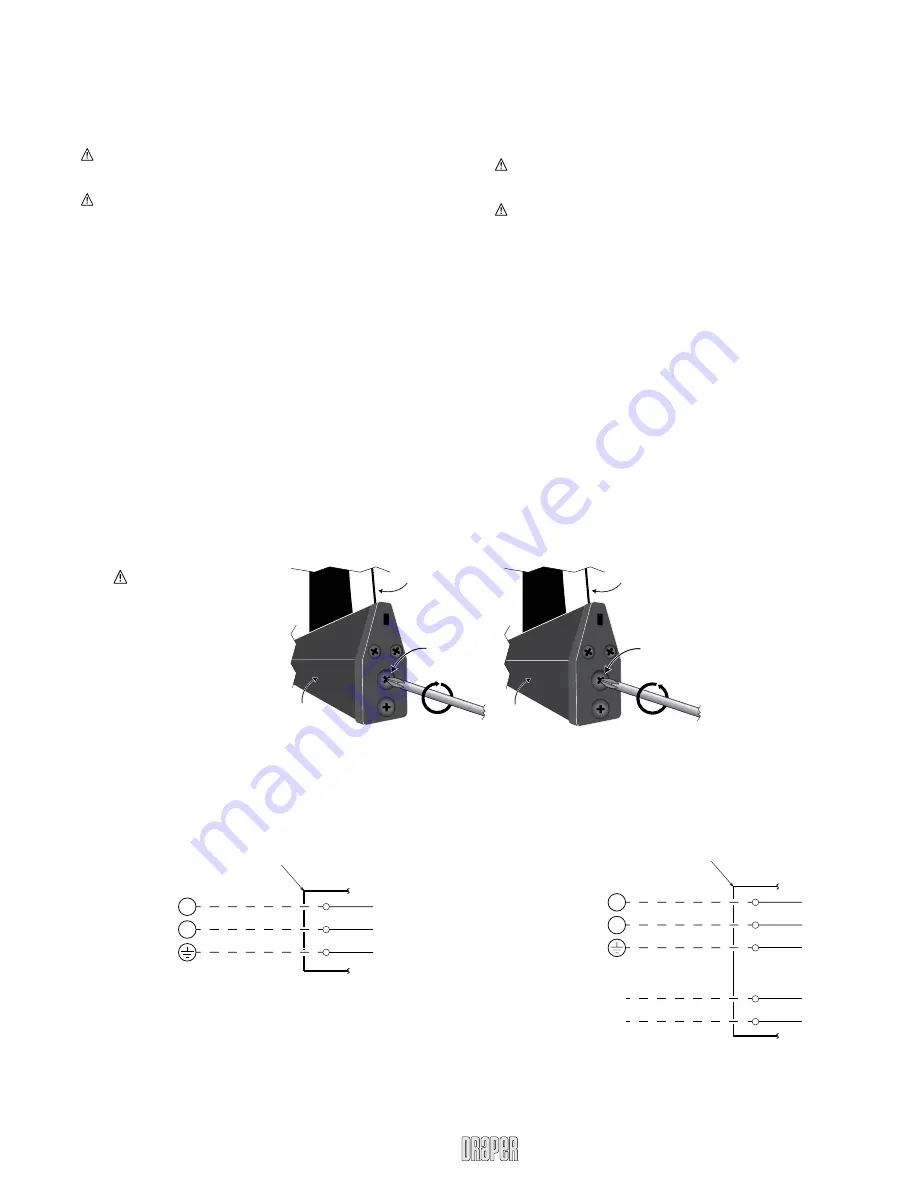

Wiring Diagrams for Optional Built-in Controls

Adjustments (Screen Motor)

Please Note: Screen limits are factory set for optimum performance of

the screen. A procedure is outlined below for minor tweaks, but any

adjustment of these limits may negatively affect the flatness of the

screen surface and could also void the warranty. Please check with

Draper prior to resetting screen limits.

CAUTION: Always be prepared to shut screen off manually when new

adjustment is being tested. Screen may be severely damaged if viewing

surface is allowed to run too far up or too far down.

C

AUTION: Be sure all switches are in “off” position before adjusting

limit switches.

“DOWN” LIMIT SWITCH

—Down stopping position can be adjusted by turn-

ing the white socket (located on the motor end of screen roller). Turning the

socket counterclockwise will allow the roller to run farther down. Turning it

clockwise will shorten operation, causing it to stop sooner. One full revolution

of the socket will alter the stopping position of the viewing surface by approxi-

mately 32 mm.

“UP” LIMIT SWITCH—

Up stopping position can be adjusted by turning the

yellow socket (located on motor end of screen). Turning the socket counter-

clockwise will allow the roller to run farther up. Turning it clockwise will cause

the roller to stop sooner. One full revolution of the socket will alter the stopping

position of the viewing surface by approximately 32 mm.

AT NO TIME SHOULD SURFACE BE UNROLLED ENOUGH TO EXPOSE

ANY PART OF SCREEN ROLLER.

If you encounter any difficulties installing or servicing your Access MultiView

screen, call your dealer or Draper, Inc., Spiceland, Ind., (765) 987-7999 or fax

(765) 987-1689.

Adjustments (Masking Motor)

Please Note: Screen limits are factory set for optimum performance of

the screen. A procedure is outlined below for minor tweaks, but any

adjustment of these limits may negatively affect the flatness of the

screen surface and could also void the warranty. Please check with

Draper prior to resetting screen limits.

CAUTION: Always be prepared to shut screen off manually when new

adjustment is being tested. Screen may be severely damaged if viewing

surface is allowed to run too far up or too far down.

C

AUTION: Be sure all switches are in “off” position before adjusting

limit switches.

“DOWN”

LIMIT SWITCH—Down stopping position can be adjusted by turning

knob #2 (on motor end of masking roller). Turning the knob counterclockwise

will allow the roller to run farther down. Turning it clockwise will shorten opera-

tion, causing it to stop sooner.

“UP” LIMIT SWITCH—

Up stopping position can be adjusted by turning knob

#1 (on the motor end of masking roller). Turning the knob counterclockwise

will allow the roller to run farther up. Turning it clockwise will cause the roller to

stop sooner.

Built-in Video Interface Control

Junction box at

left end of screen

Internal screen wiring

White (Neutral)

Black (Hot)

Green (Ground)

Dashed wiring

by electrician

220V AC supply

Trigger signal

VIC220 (220 V AC, white cord & plug)

VIC12 (12 VDC, brown & orange leads)

N

L1

Built-in Low Voltage Control

Junction box at

left end of screen

Internal screen wiring

White (Neutral)

Black (Hot)

Green (Ground)

Dashed wiring

by electrician

220V AC supply

N

L1

www.draperinc.com

(765) 987-7999

C

OU

NTER-CLO

CK

W

IS

E

ADJUSTMENT

SCREW

TENSIONING

CABLE

DOWEL

TO

RE

LEASE TEN

SIO

N

T

U

R

N

CLOCKW

IS

E

ADJUSTMENT

SCREW

TENSIONING

CABLE

DOWEL

TO

IN

CREASE TEN

SIO

N

T

U

R

N

Tab-Tension Adjustment Procedure

Draper’s Tab-Tensioning System is factory-set, and under normal circumstances will not require field adjustment.

If, however, you notice wrinkles, waves or other indications that the tensioning cables need to be adjusted, follow the procedure below.

1

Determine which side requires adjustment.

2

Secure dowel with one hand.

3

Using Phillips-head screwdriver, depress spring-loaded adjustment screw and slowly turn

CLOCKWISE TO INCREASE

tension,

or

COUNTER-CLOCKWISE TO RELEASE

tension. The screw adjusts in ¼ turn increments. Adjust only

one increment

(¼ turn) at a time

4

If problem is not corrected, leave screen in position for 24 hours to allow surface material to stretch into position.

5

If problem still is not corrected, repeat steps 2 and 3.

Caution: Do not touch

or bend surface.