Chemdose Manual

7

Pre Operation Checklist

T

REATMENT

A

REA

:

A. Make sure that the treatment area is vacant. No humans or pets should be present.

B. Post all hazard signs before application.

C. Follow all E.P.A. and W.P.S. guidelines. Follow all chemical label directions.

C

HEMDOSE

:

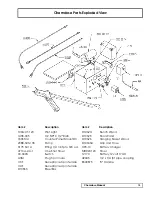

A. Fit the Chemdose with the proper wand for your application situation. Make sure that

the wand does not leak from any of the fittings.

B. Dial the dosing knob to the correct output setting. Dial the interval to the desired length

of time between shots. Make this time long enough to prevent rushing and inaccurate appli-

cation.

C. Reset the cycle counter. Make sure to keep track of the number of shots used on a full

charge to ensure proper dosing.

D. Test the Chemdose with clear water. Use each button separately to ensure proper opera-

tion of both. Make sure that nothing is blocking the output. Proper flow should be an even,

aerated flow.

E. Uncoil the hose and make sure that there are no kinks in the hose.

F. Mix chemical solution according to label guidelines. (see "Application and Chemical

Mixing" section below)

Application

1. WARNING: Follow all EPA Guidelines on the handling, application, and re-entry periods

for chemicals. Only crops listed on the label should be treated.

2. Pre Water plants to be treated. Most applications of drench products work best when the

plant has been pre-watered. Ensure that the media is thoroughly saturated. Some chemi-

cals can be applied to dry soil. Always defer to the chemical manufacturer recommendations

for application.

3. Determine how you will treat the area and whether or not you will be spot treating individ-

ual plants or treating all the plants in an area. Choose the correct button for the method

you prefer.