8

DR

®

TRIMMER/MOWER™ BEAVER BLADE

®

Chapter 4: Maintaining The DR

®

TRIMMER/MOWER™ BEAVER BLADE

®

Regular maintenance is the way to ensure the best performance and long life

of your BEAVER BLADE. Please refer to this manual for maintenance

procedures.

Use the BEAVER BLADE for cutting wood, brush and small trees ONLY.

It's a good practice to sharpen the BEAVER BLADE before each use. This

allows you to maintain the proper cutting angle of the teeth before the

chain gets too dull. See the following page for sharpening instructions.

The BEAVER BLADE does not need to be oiled.

To avoid premature dulling, keep the blade out of contact with the

ground.

If you are planning to do heavy brush cutting, please consider purchasing

the aluminum Mow-Ball™ Support, which better withstands the heat

created by the BEAVER BLADE and is more durable under heavy use.

If you have any questions at all, please feel free to contact us at

www.DRpower.com or call toll-free 1(800) DR-OWNER (376- 9637) and one

of our Customer Service Representatives will be happy to help you.

Sharpening the BEAVER BLADE

Tools Needed:

3/16" (4.8mm) saw chain file.

Flat file

Gloves

Safety Glasses

1.

Remove the BEAVER BLADE from the cutting (or trimming) head.

Leave the chain on the blade.

2.

Draw a mark on the chain or BEAVER BLADE where you will begin

sharpening.

TIP:

Using a vise to hold the Beaver Blade while sharpening will make it

easier to make consistent sharpening strokes.

Note:

File the chain with a light pressure into the cutting edge of the tooth. Do not bear down on the file. Give each tooth the same

number of strokes. The teeth are made of a relatively soft metal. It is not necessary to remove a lot of metal.

3.

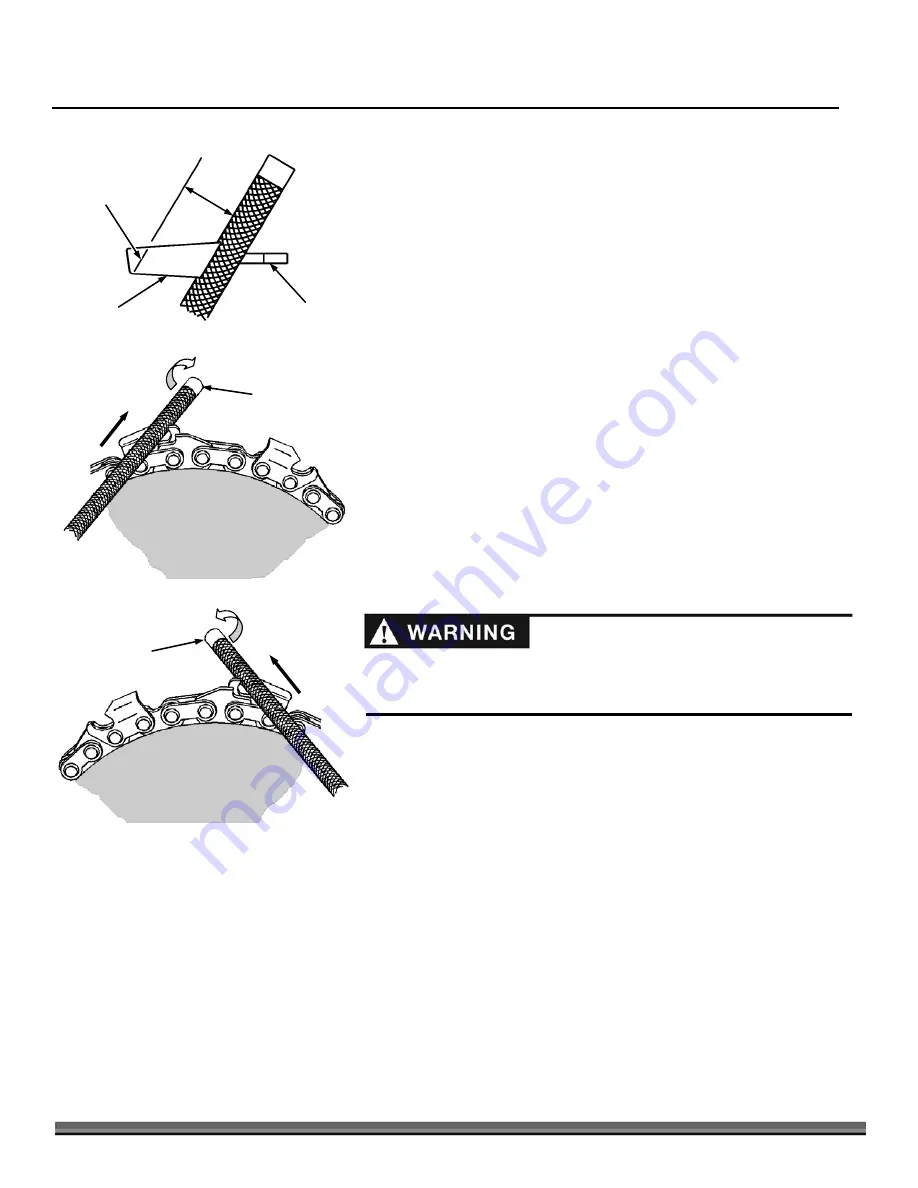

While holding the beaver blade in a standing (vertical) position, Place the round file into the tooth at the same angle as

the cutting edge of the tooth

(Figure 7)

. Lightly push the file across the cutting edge and through the tooth, twisting the

file a half turn with each stroke

(Figure 8)

.

4.

Skip the next tooth (because it is facing the opposite direction), and sharpen the following tooth and so on. When you get

back to your mark, you are finished with ONE side of the BEAVER BLADE.

5.

Turn the BEAVER BLADE around to sharpen the other side. Change the angle of the round file to follow the angle of the

cutting edge for teeth on this side

(Figure 9

). Start sharpening at your mark. Sharpen the teeth that have not yet been

touched. Remember to pay attention to the angle of the file on the tooth and use the same number of strokes per tooth.

File at Same

Angle as Mark

Tooth

Raker

Figure 7

Sharpen Angle/

Wear Mark

Round File

First Side

Figure 8

Round File

Second Side

Figure 9

Before performing any maintenance procedure or inspection, stop the engine,

wait five minutes to allow all parts to cool. Disconnect the spark plug wire,

keeping it away from the spark plug.