contact us at

www.DRpower.com

29

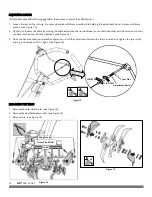

Parts List

Note: Part numbers listed are available through DR Power Equipment. Not all parts appear on all diagrams.

Ref# Part#

Description

1

41522

Gear Box Assembly

2

41686

Bolt M8X20

3

41523

Flat Washer 8

37

41524

Flange Lock Nut M8

63

41525

Engine Shaft Washer

64

41526

Lock Nut M10

65

41527

Counterweight 2

66

41528

Gear Cover Mount Bracket

67

33787

Clip 1.8

68

41529

Right Wheel Assy.

69

41530

Pin Shaft B8x45

70

30250

Flat Washer 10

71

41531

Direction Indicator Weldment

72

41532

Shift Rod

73

41533

Spring Pin 5x30

74

41534

Gear Shift Markable Plate

75

41535

Bolt M6x16

76

41536

Engine

77

41537

Pulley

78

41538

Key B5x4.76x40

79

41539

Screw M8x12

80

41540

Blade Mount Bracket

81

41541

Pin B10x45

82

41542

R Clip 2.5

83

41543

Bolt M10x30

84

41544

Blade 2

85

41545

Swing Nut

86

41546

Adjustable Side Shield B1

87

41547

Bolt M8x20

88

41548

Side Tine Shield

89

41549

B Style Sprig Nut M8

90

41550

Blade 1

91

41551

Lock Nut M8

92

41552

Bolt M8x25

93

41553

Tine Shield

94

41554

Spring

95

41555

Pin

96

41556

C-Clip

97

41557

Handle Mount Bracket 2

98

41558

Handle Mount Bracket 1

99

41559

Handle Support Frame

100 41560

Bolt M10x25

101 41561

Nut M8

102 41562

Upper Handle

103 41563

Lock Lever

104 41564

Lever Knob

105 41565

Bolt M8x85

106 41566

Throttle Cable

107 41567

Throttle Lever Assy.

108 41568

Screw M6x50

109 41569

Lock Nut M6

110 41570

Tensioner Pulley Cable

111 41571

Pulley Cable Drag Rod

Ref# Part#

Description

113 41573

End Cap 25

114 41574

Upper Handle Sleeve

115 41575

Brake Connecting Plate

116 41576

Shift Lever Knob

117 41577

Shift Lever

118 41578

Bushing

119 41579

Support Sleeve

120 41580

Bolt M8x75

121 41581

Spring

122 41582

Pin Bracket

123 41583

Rubber Cap

124 41584

Serrated Rear Shield

125 41585

Hinge

126 41586

Hinge Shaft

127 41587

Limiter Pin

128 41588

Spring Washer 5

129 41589

Bolt

130 41590

Adjustable Side Shield B2

131 41591

Bolt M10x25

132 41592

Spacer 3

133 41593

Screw M5x10

134 41594

Bolt M5x12

135 41595

Long Bolt

136 41596

Cable Fixation Clamp

137 41597

Belt Cover Mount Bracket

138 41598

Belt Pulley

139 41599

Lock Nut M5

140 41600

Key A5x20

141 41601

Depth Stake 3

142 41602

Belt 4LXP1308

143 41603

Depth Stake 2

144 41604

Belt Cover

145 41605

Left Wheel Assy.

146 41606

Spacer 2

147 41607

Flange Lock Nut 10

148 41608

C-Clip 9

149 41609

Tensioner Pulley

150 41610

Bushing

151 41611

Wheel Bracket Weldment

152 41612

Bolt 5/16 - 24 UNF*25

153 41613

Spring Washer 8

154 41614

Bolt M10x290

155 41615

Counterweight 1

156 41616

Bolt M8x40

157 41617

Spacer 1

158 41618

Tensioner Pulley Shaft

159 41619

Bolt M8x30

160 41620

Belt Block Rod

161 41621

Big Flat Washer 8

162 41622

Engine Protector Weldment

163 41623

Spacer 4

164 41624

Bolt M8x16

165 41625

Bearing 6004-2RS